In the fast-paced world of printing, choosing the right equipment is crucial. A Rotary Printing Machine stands out for its efficiency and versatility. Renowned industry expert, John Smith, once stated, "Investing in a Rotary Printing Machine can elevate your production quality significantly." His insights reflect a growing trend among businesses that demand high-quality prints.

Many companies struggle with outdated printing technology. They often face long production times and inconsistent results. Rotary Printing Machines address these challenges head-on. These machines provide faster printing speeds and improved design options. As John Smith highlights, the reliability of a Rotary Printing Machine ensures that businesses stay competitive.

However, it’s essential to evaluate specific needs. The initial investment might be significant for some. Yet, the long-term savings and enhanced output can outweigh these costs. Reflecting on such decisions is vital. A Rotary Printing Machine might not be for everyone, but for those ready to innovate, it offers a powerful solution.

When it comes to printing, rotary machines stand out for several reasons. They offer speed and efficiency that traditional methods struggle to match. A rotary printer can produce large volumes quickly, reducing the amount of time spent on each project. This is crucial for businesses needing to meet tight deadlines. The machine’s continuous feed system ensures that printing never stops, allowing for a constant workflow.

Quality is another significant advantage. Rotary printing provides vibrant colors and sharp images. These machines utilize advanced inks that adhere better to various materials. This means that the end product often looks more professional. While traditional methods may require extensive setups, rotary printers can switch between jobs with minimal delays.

However, embracing rotary printing isn’t without challenges. The initial investment can be high for smaller businesses. Additionally, understanding the machine’s complexities requires training. Not every operator can easily adapt to this technology. Sometimes, this learning curve leads to mistakes, which can slow down production. It’s essential for businesses to consider these factors when choosing the right printing method.

| Advantages | Rotary Printing Machines | Traditional Printing Methods |

|---|---|---|

| Speed | High-speed production, suitable for large runs | Slower production rates |

| Quality | Consistent high-quality prints with fine details | Quality may vary between runs |

| Material Versatility | Can print on a variety of materials including plastic and metal | Limited material compatibility |

| Cost Efficiency | Lower cost per unit on large runs | Higher cost per unit for small batches |

| Setup Time | Quick setup for long runs | Longer setup time for each job |

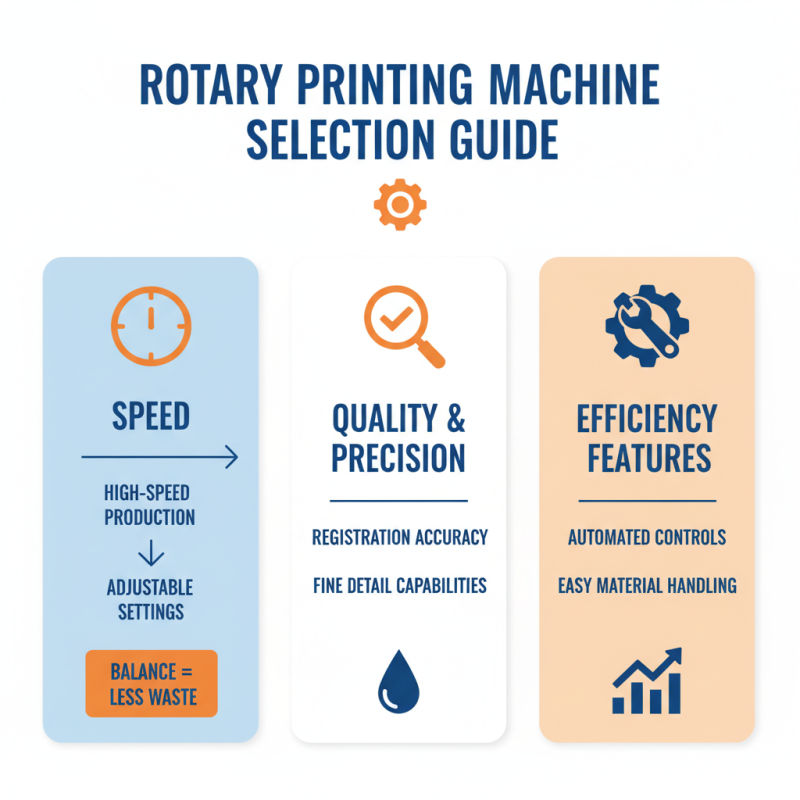

When selecting a rotary printing machine, consider key features that enhance efficiency and quality. Speed is crucial. A high-speed model can significantly boost production. Look for machines that offer adjustable printing speeds. An unnecessary rush might lead to errors and waste, so find a balance.

Ink management is another important aspect. Machines with efficient ink systems reduce spills and save costs. Some models use advanced technology to minimize ink consumption. This can be a game-changer for budget-conscious businesses. Review how easily the ink systems can be accessed for maintenance as well.

Flexibility in design is essential. A rotary printing machine should handle various print sizes and materials. Some businesses strictly rely on particular media types. This can be limiting. Consider a machine that can adapt as your needs change. Features like quick-change plates may be beneficial. However, these features might increase initial costs and require ongoing training. Reflection on how these choices align with long-term goals is vital.

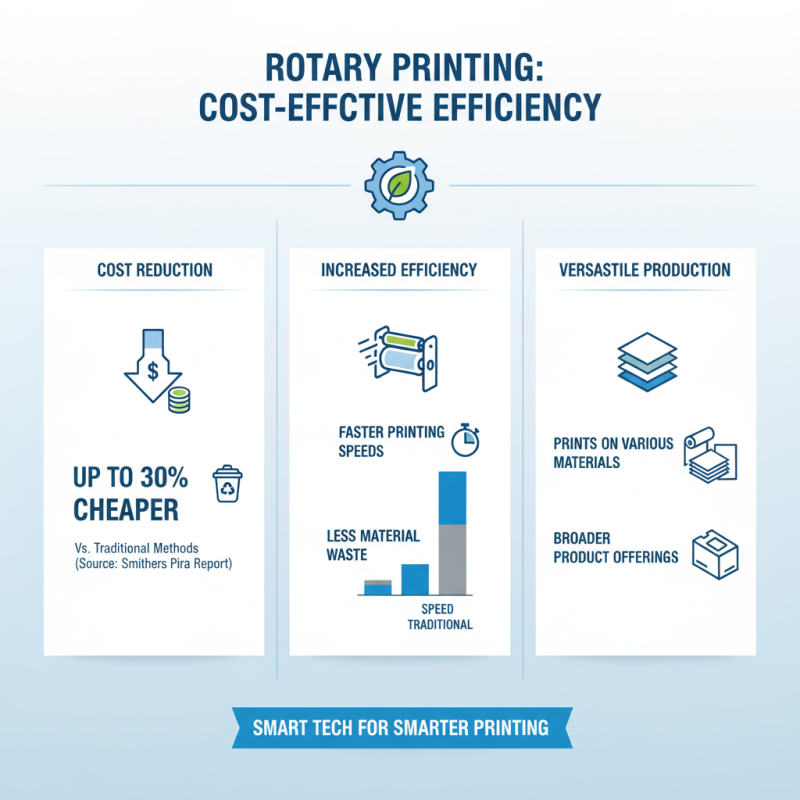

Rotary printing technology stands out for its cost-effectiveness. A report by Smithers Pira shows that rotary presses can reduce printing costs by up to 30% compared to traditional methods. This efficiency comes from faster printing speeds and less waste. Rotary machines can print on a variety of materials, further broadening product offerings.

The initial investment might seem daunting. However, the long-term savings can offset these costs. Industries report lower labor costs due to automated processes. Moreover, a study by the National Association of Printing Leaders indicates that companies using rotary printing enjoy a 20% increase in production rates. This expedited process allows businesses to fulfill larger orders quickly.

Environmental impact is another consideration. Rotary printing often uses water-based inks, which are less harmful. While some may argue about the upfront energy consumption, the overall carbon footprint is reduced through efficient operations. This dual advantage makes rotary printing not only a financially sound choice but also a sustainable one.

Rotary printing machines have found applications across various industries. In the packaging sector, these machines excel at creating vibrant labels and wrappers. Businesses benefit from high-speed production and consistent quality. Food packaging, for example, requires eye-catching designs that draw customer attention. Here, rotary printing provides just that.

Textile industries also leverage this technology. Rotary printing allows for intricate designs on fabrics, enhancing fashion appeal. The process can accommodate large runs and diverse colors, making it ideal for bulk orders. However, the initial setup can be time-consuming. Companies must invest time and resources before reaping the rewards.

Additionally, the flexibility of rotary printing caters to various materials. From plastic to paper, each medium has unique challenges. Some users struggle with ink adhesion or drying times. These technical issues necessitate ongoing improvement and experimentation. The learning curve can be steep, but the potential for creativity remains high in every industry.

Maintaining a rotary printing machine is crucial for its longevity. Regular cleaning keeps the machine running smoothly. Dust and ink residue can build up, causing issues. Using the right cleaning solutions helps to prevent damage. Check the manuals for recommended products.

Lubrication is another important aspect. A well-lubricated machine operates quietly and efficiently. Use high-quality lubricants designed for printing equipment. Monitor wear and tear on moving parts. Replace them when necessary to avoid costly breakdowns. Neglecting these details can lead to unexpected downtimes.

Operator training plays a vital role too. Ensure that staff understand how to handle the machine correctly. They should know the common problems and how to solve them. Mistakes happen, but awareness minimizes risks. Each little error can accumulate, causing larger failures down the line. Regular training sessions reinforce knowledge and improve overall performance.