In the world of fashion and personalization, the method of Machine Print On T Shirt has revolutionized how we express creativity and individuality. This cutting-edge technology harnesses the principles of art and science, combining state-of-the-art machinery with innovative design processes to bring unique visions to life on fabric. As we delve into the intricacies of this technique, we'll explore the various methods of machine printing, the materials used, and the impact of digital technology on creativity. More than just a manufacturing process, machine printing serves as a canvas for artists and designers, allowing them to push boundaries and explore new avenues of expression. From vibrant graphics to intricate patterns, the possibilities are limitless, inviting both novices and seasoned creators to discover their artistic potential. Join us on this journey as we uncover the science behind machine printing on T-shirts and unveil the countless ways it unleashes creativity in the textile arts.

The workflow of machine printing for T-shirt design involves several key steps that integrate technology and creativity. At the heart of this process is a digital artwork creation, where designers use software tools such as Adobe Illustrator or CorelDRAW to develop vibrant and unique graphics. According to a report by Grand View Research, the global custom T-shirt printing market size was valued at approximately $3.64 billion in 2020 and is expected to expand significantly, reaching $10.14 billion by 2027. This growth underscores the increasing demand for personalized apparel, driving innovation in printing technologies.

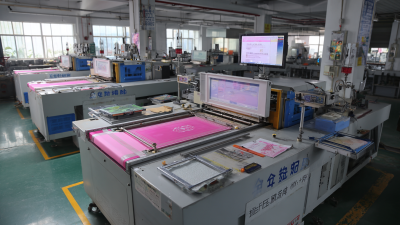

Once the design is finalized, the workflow progresses to the printing phase, where techniques like Direct-to-Garment (DTG) printing and screen printing come into play. DTG printing, which allows for detailed designs to be directly printed onto the fabric, accounts for about 20% of the T-shirt printing market, as noted in a report by Mordor Intelligence. This method is gaining popularity due to its ability to produce high-quality prints with minimal setup time. As the final step, the shirts undergo quality control processes to ensure that the prints meet the expected standards, further enhancing the overall production efficacy.

When it comes to printing designs on T-shirts, two primary techniques dominate the market: Direct-to-Garment (DTG) printing and screen printing. Each method has its strengths and weaknesses, making them suitable for different production needs. According to a recent industry report by Smithers Pira, the global market for digital textile printing is projected to reach $4.9 billion by 2024, highlighting the increasing preference for DTG printing. This technique allows for high-resolution images with a wide range of colors, making it ideal for small orders and intricate designs. DTG printing is particularly advantageous for custom garments, as it minimizes setup times and reduces waste by printing only what is needed.

In contrast, screen printing remains the go-to choice for large-scale production due to its cost-effectiveness and durability. The printing process involves creating stencils for each color, which can be time-consuming but results in vibrant and long-lasting prints. The Specialty Graphic Imaging Association (SGIA) reported that screen printing accounts for over 80% of the T-shirt printing market, emphasizing its dominance in bulk orders. While the initial setup cost is higher, screen printing's efficiency in mass production makes it a preferred method for brands aiming to fulfill larger orders while maintaining quality. Both techniques have their place in the market, catering to different customer demands and production goals.

| Printing Technique | Description | Pros | Cons | Best Use Case |

|---|---|---|---|---|

| Direct-to-Garment (DTG) | A method that uses inkjet technology to print designs directly onto garments. | High detail, unlimited colors, ideal for small runs. | Slower production speed, limited fabric types, may require pretreatment. | Small batches and intricate designs. |

| Screen Printing | A traditional printing technique that uses screens and stencils to transfer ink onto a surface. | Durable, vibrant colors, cost-effective for large orders. | Setup time and cost can be high, limited colors for complex designs. | High-volume orders and simple designs. |

| Heat Transfer | A method that involves printing a design onto a special transfer paper and then applying heat to transfer it to the garment. | Easy to use, good for customizing individual shirts. | Less durable than screen printing, can feel heavy on the fabric. | Personalization and small orders. |

| Sublimation Printing | Uses heat to transfer dye onto materials like polyester, creating vibrant and durable designs. | Bright colors, long-lasting results, works well on synthetic fabrics. | Limited to polyester or specially coated materials, not suitable for dark fabrics. | All-over prints and polyester garments. |

The demand for custom printed apparel is steadily rising, particularly in the digital textile printing market. As of 2020, the market was valued at approximately $147.4 million, and it's poised for significant growth, projected to reach around $311.7 million by 2028. This increase highlights a trend among consumers toward personalized clothing options, particularly in t-shirts, where unique designs can express individuality and creative flair.

Tips: When venturing into custom t-shirt printing, always stay updated on the latest printing technologies. Innovations in ink and printing methods can enhance print quality while reducing costs. Additionally, consider utilizing social media platforms to build an engaging brand presence that resonates with potential customers, showcasing your creativity and customization options effectively.

Another notable market trend is the growth in demand for healthcare uniforms, which is expected to rise from $10.7 billion in 2025 to over $20.4 billion by 2032, illustrating the increasing emphasis on tailored workwear in various industries. Tapping into niche markets like medical apparel can help businesses diversify their offerings and boost sales.

Tips: To cater to niche markets, conduct thorough research into customer preferences and emerging trends, enabling you to tailor your products effectively. Engaging directly with your target audience through surveys can provide valuable insights that inform your designs and marketing strategies.

The rise of digital printing technologies has transformed the t-shirt industry, making it easier than ever to unleash artistic creativity. However, as we embrace these innovations, it’s crucial to consider their environmental impact. Traditional screen printing methods often rely on harmful inks and generate significant waste. In contrast, digital printing utilizes water-based inks and is typically more efficient, producing less waste and reducing harmful emissions.

To minimize the environmental footprint of t-shirt printing, here are a few tips: Firstly, choose eco-friendly inks that are biodegradable and less toxic. Secondly, consider sourcing apparel made from organic or recycled materials, as this reduces the need for virgin resources. Lastly, practice mindful production by using print-on-demand services, thereby minimizing excess inventory and ensuring that every shirt produced meets the exact demand.

By prioritizing sustainable practices in digital printing, we can create a more responsible fashion industry. These advancements not only make artistic expression more accessible but also pave the way for a greener future in apparel production.

The integration of data analytics into the T-shirt printing industry is revolutionizing the creative process. By analyzing consumer preferences and trends, companies can tailor their designs to meet the evolving tastes of their audience. This data-driven approach allows for the identification of popular themes, colors, and styles, ensuring that new prints resonate with customers. By leveraging insights from social media, sales patterns, and market research, designers can make informed decisions that enhance the relevance and appeal of their printed creations.

Moreover, analytics not only aids in design but also boosts operational efficiency. By understanding production trends and inventory management through data analysis, businesses can minimize waste and optimize their supply chain. This creates a more sustainable model while allowing for quicker turnarounds on new designs. As machine printing technology continues to advance, the ability to use data to spark creativity and streamline production processes will become increasingly vital for staying competitive in the ever-evolving fashion landscape.