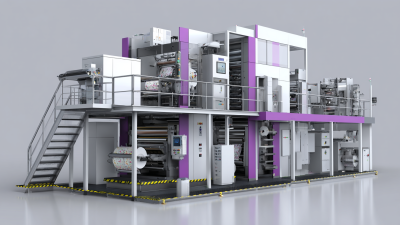

In the ever-evolving world of printing technology, the Rotary Printing Machine has emerged as a pivotal player, reshaping the industry landscape. According to a recent report by Smithers Pira, the global market for rotary printing is projected to reach $10.3 billion by 2025, driven by increasing demand for high-speed and high-quality print production. This technology is not only enhancing operational efficiency but also allowing businesses to meet the rising consumer expectations for diverse and customizable print products.

As we delve into "The Ultimate Guide to Mastering Rotary Printing Machine Techniques for Your Business," it is crucial to explore the intricate processes, innovative techniques, and strategic applications that can elevate your printing operations and ensure sustained business growth in a competitive market. Embracing the advancements in rotary printing is no longer an option; it's a necessity for businesses aiming to thrive in the future of printing.

Understanding the basics of rotary printing machines is essential for any business looking to enhance operational efficiency. These machines have evolved significantly, with recent predictions highlighting advancements that will shape the printing landscape by 2025. For instance, during events like Labelexpo Southeast Asia 2025, new technologies will be showcased that promise to streamline processes and reduce waste. By integrating cutting-edge design and sustainable practices, businesses can not only improve productivity but also foster eco-friendly manufacturing techniques.

Tip 1: Familiarize yourself with the components and working principles of rotary printing machines. Understanding how different inks and substrates interact can lead to better job performance and reduce material costs.

The rise of low-carbon manufacturing is also influencing rotary printing technologies. As companies increasingly adopt ESG principles, exploring innovative solutions like 3D printing in conjunction with rotary machines could provide significant competitive advantages. This alignment with sustainability not only meets regulatory demands but can also appeal to a growing base of environmentally conscious consumers.

Tip 2: Stay updated with industry reports and technology previews to anticipate shifts in machine capabilities. Attending expos and engaging with thought leaders in the printing domain can equip you with valuable insights and inspire operational improvements.

Setting up a rotary printing machine with precision is crucial for achieving high-quality print results and optimizing production efficiency. To begin, ensuring that all components are properly calibrated is essential. Start by checking the alignment of the printing plates and rollers; any misalignment can lead to distorted images and uneven ink distribution. Utilizing a laser alignment tool can greatly simplify this process, allowing for minute adjustments that can make a significant difference in print quality.

Next, pay attention to the ink viscosity and consistency. The right ink formulation is vital for achieving the desired color outcomes and smooth printing on various substrates. Regularly monitor ink properties and adjust as necessary to avoid issues like smearing or drying too quickly on the substrate. Additionally, experimenting with different anilox rolls can help optimize ink transfer, enhancing the clarity and vibrancy of prints. With these essential techniques, you can ensure that your rotary printing machine operates at its best, delivering exceptional results that will set your business apart in a competitive market.

Maintaining rotary printing machines is crucial for ensuring their longevity and optimal performance. Regular maintenance not only reduces downtime but also enhances the quality of your printed materials. One of the key tips is to conduct routine inspections. Check all components, including the printing plates, rollers, and ink systems, for wear and tear. Addressing minor issues promptly can prevent costly repairs down the line.

Another essential aspect is to keep the equipment clean. After each job, remove any leftover ink and debris to avoid buildup, which can lead to malfunction or deterioration. Utilize appropriate cleaning solutions and tools specifically designed for your rotary printing machine to maintain its condition. Additionally, ensure that lubrication points are serviced according to the manufacturer’s recommendations, as this will help in maintaining smooth operation and extending the machine's lifespan.

Lastly, investing in training for your staff on proper operational techniques can significantly contribute to the equipment's longevity. Knowledgeable operators can identify potential issues early and make adjustments to prevent excessive wear. By following these maintenance tips, you not only protect your investment but also ensure consistent and high-quality output for your business.

| Maintenance Tip | Description | Frequency | Estimated Time | Impact on Longevity |

|---|---|---|---|---|

| Clean Print Heads | Regularly clean print heads to prevent clogging and ensure quality printing. | Weekly | 30 minutes | High |

| Lubricate Moving Parts | Lubricate gears and belts to reduce friction and wear. | Monthly | 1 hour | Medium |

| Inspect Electrical Connections | Check and tighten all electrical connections to prevent failures. | Monthly | 30 minutes | High |

| Replace Worn Parts | Periodically replace any worn or damaged parts. | As Needed | Varies | Very High |

| Calibrate the Machine | Ensure accuracy in printing by calibrating the machine regularly. | Quarterly | 2 hours | High |

Innovative printing techniques have become essential for businesses aiming to enhance quality and reduce waste in the highly competitive printing industry. According to a recent study by Smithers Pira, the global printing market is projected to reach $980 billion by 2024, with rotary printing machines playing a significant role in this growth. These machines are known for their ability to produce high-quality prints at greater speeds, which not only boosts productivity but also minimizes material waste significantly. Implementing advanced rotary printing techniques can lead to a reduction in waste by as much as 30% when compared to traditional methods.

Innovative printing techniques have become essential for businesses aiming to enhance quality and reduce waste in the highly competitive printing industry. According to a recent study by Smithers Pira, the global printing market is projected to reach $980 billion by 2024, with rotary printing machines playing a significant role in this growth. These machines are known for their ability to produce high-quality prints at greater speeds, which not only boosts productivity but also minimizes material waste significantly. Implementing advanced rotary printing techniques can lead to a reduction in waste by as much as 30% when compared to traditional methods.

To optimize the use of rotary printing machines, consider these tips: First, invest in regular maintenance schedules to ensure the machines operate at peak efficiency. This can help prevent issues that might cause excess waste or downtimes. Second, focus on selecting the right substrates and inks, as using incompatible materials can lead to more frequent errors and defects in printing. Lastly, training your workforce on the latest printing technologies is crucial; skilled operators can maximize output while maintaining high-quality standards.

Embracing these innovations will not only elevate your printing business's standard but also contribute to sustainability efforts, making your operation environmentally friendly while staying competitive in the market.

Investing in advanced rotary printing technology offers significant advantages for businesses aiming to enhance their production capabilities. Rotary printing, known for its speed and efficiency, can deliver high-quality results while minimizing waste. Businesses leveraging this technology can benefit from reduced operational costs and increased output, leading to a more competitive edge in the market. Moreover, as industries continue to evolve, integrating advanced technology can be the key to staying ahead of competitors.

The recent development of cutting-edge components, such as high-performance adapters for semiconductor packaging, highlights the importance of innovation in manufacturing processes. Just like these advancements in the semiconductor sector, rotary printing technology is evolving to meet the more demanding requirements of various industries. By investing in such progressive equipment, businesses can ensure they are equipped to handle complex designs and enhance their product offerings, ultimately fostering growth and profitability in an ever-changing marketplace.