In the rapidly evolving world of custom apparel, the importance of T Shirt Design Machines has become increasingly prominent. According to a recent market report by Grand View Research, the global custom t-shirt printing market is projected to reach USD 3.64 billion by 2025, underscoring the growing demand for personalized clothing. As consumers seek unique ways to express themselves, T Shirt Design Machines have emerged as essential tools for both entrepreneurs and hobbyists looking to create stunning custom apparel.

Industry expert Dr. Emily Chen, a leading researcher in textile technology, emphasizes the significance of these machines by stating, "With the advancement of design technology, T Shirt Design Machines empower creators to turn their visions into reality with unprecedented precision and efficiency." This evolution not only enhances the creative potential for individuals but also supports small business owners in meeting the diverse needs of their customers.

As we delve into the top 10 T Shirt Design Machines available in the market today, we will explore how these innovative tools can revolutionize the way we approach custom apparel design, providing insights into their features, capabilities, and overall impact on the industry.

When it comes to creating stunning custom apparel, selecting the right type of T-shirt design machine is crucial. One of the most popular options is the direct-to-garment (DTG) printer, which allows for intricate designs and vibrant color printing directly onto the fabric. This technology is favored by many designers due to its ability to print on a variety of materials and its suitability for small-batch orders.

DTG printers excel in detail, making them ideal for complex graphics and patterns, which appeals to artists and businesses looking to create unique apparel.

Another excellent choice for custom T-shirt production is the heat transfer vinyl (HTV) machine. This method involves cutting designs from colored vinyl and applying them to shirts using a heat press. HTV machines are versatile and cost-effective, making them perfect for those who want to produce custom designs quickly.

Unlike DTG, HTV can be used for a wide range of materials and offers a tactile feel that can elevate the garment's overall appeal. The combination of simplicity and durability makes HTV a favorite among small business owners and hobbyists alike, ensuring they can create quality apparel that stands out in the market.

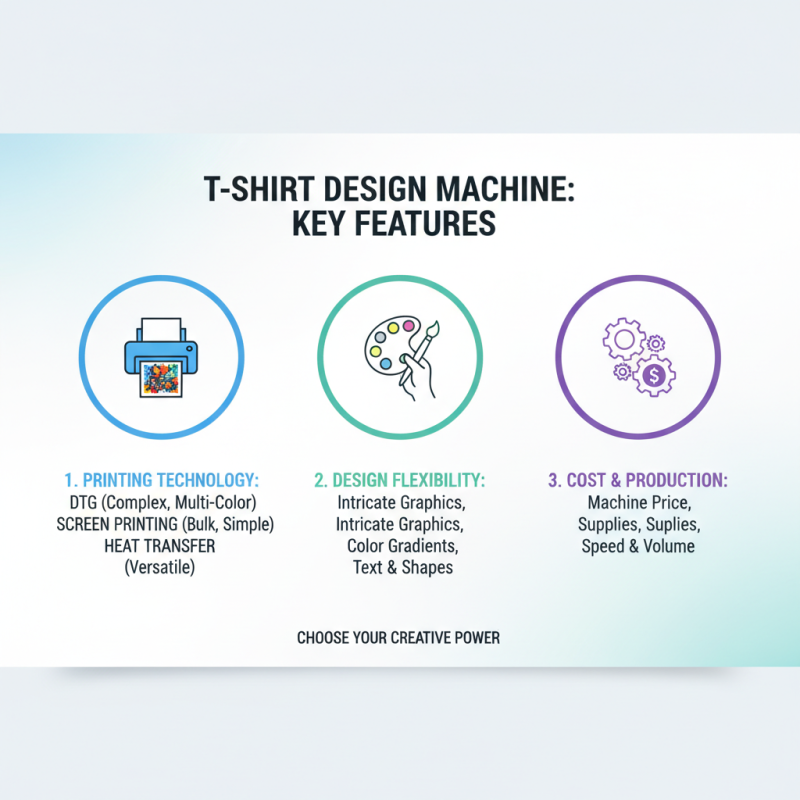

When selecting a t-shirt design machine, it’s essential to focus on several key features that can greatly impact your creative process. First and foremost, consider the printing technology employed by the machine. Options such as direct-to-garment (DTG), screen printing, and heat transfer each offer unique advantages depending on the complexity and vibrancy of the designs you wish to create. DTG machines, for instance, are ideal for intricate designs with multiple colors, while screen printing can be more cost-effective for bulk orders with simpler graphics.

Another crucial aspect to evaluate is the machine's compatibility with various fabric types. A versatile t-shirt design machine should accommodate different materials like cotton, polyester, or blends to expand your design possibilities. Additionally, examine the machine's ease of use, including features like user-friendly software for design creation and straightforward operation. A responsive customer support system is also essential to assist with any technical issues that may arise during production. By prioritizing these features, you can ensure that the t-shirt design machine you choose will meet your creative needs and enhance your apparel business's capabilities.

When it comes to creating stunning custom apparel, selecting the right t-shirt design machine is crucial. This article compares the top 10 t-shirt design machines available, providing an overview of their features, capabilities, and ease of use. Each machine varies in its approach, from digital printing and heat transfer to screen printing, catering to different needs and levels of expertise. For instance, some machines are tailored for beginners with user-friendly interfaces and all-in-one functionalities, while others appeal to professionals seeking high-quality output and advanced design options.

In evaluating these machines, several factors are considered, such as print resolution, versatility in materials, and speed of production. Users can find machines that excel in vibrant color reproduction and detailed designs, essential for eye-catching apparel. Additionally, the comparison highlights the importance of maintenance and the availability of support, providing insight into long-term investment considerations. Whether you're a hobbyist aiming to personalize gifts or a business owner looking to expand your product line, understanding the strengths and weaknesses of each t-shirt design machine is key to making an informed choice.

When it comes to using T-shirt design machines for creating stunning custom apparel, the process can be both enjoyable and rewarding. First, familiarize yourself with the machine's functionalities. These machines often come equipped with user-friendly software that allows you to experiment with various design elements, including typography, graphics, and colors. Start by brainstorming ideas and sketching out designs on paper or using digital tools. Remember that simplicity can often lead to the most effective designs, so aim for a balance between creativity and clarity.

Once you’ve settled on a design, it’s time to bring it to life using the T-shirt design machine. Upload your designs to the software and adjust any necessary settings, such as size and placement on the fabric. It’s crucial to choose the right material for your shirts, as this can greatly impact the final product. Consider the different printing techniques available, such as heat transfer, direct-to-garment, or screen printing, as they each yield varying results. Following the machine’s instructions carefully will help ensure that your creations come out looking professional and vibrant. With practice and experimentation, you’ll quickly develop a knack for producing eye-catching custom apparel that stands out.

| Machine Type | Print Technology | Max Print Size | User Rating | Price Range |

|---|---|---|---|---|

| Direct-to-Garment (DTG) | Inkjet | 14" x 18" | 4.5/5 | $10,000 - $30,000 |

| Screen Printing Machine | Screen Print | 20" x 24" | 4.7/5 | $5,000 - $15,000 |

| Heat Press Machine | Heat Transfer | 15" x 15" | 4.3/5 | $200 - $2,000 |

| Sublimation Printer | Sublimation | 13" x 19" | 4.6/5 | $300 - $1,500 |

| Vinyl Cutter | Cutting | 15" x 28" | 4.4/5 | $200 - $2,500 |

| Laser Engraving Machine | Laser | 12" x 20" | 4.8/5 | $10,000 - $40,000 |

| Embroidery Machine | Embroidery | 5" x 7" | 4.5/5 | $1,000 - $10,000 |

| 3D Printer | 3D Printing | 10" x 10" | 4.2/5 | $500 - $3,000 |

| Flatbed Printer | UV | 24" x 36" | 4.6/5 | $15,000 - $50,000 |

| Digital Textile Printer | Digital Printing | 16" x 20" | 4.7/5 | $8,000 - $35,000 |

Maintaining your T-shirt design machine is essential for ensuring its longevity and efficiency. A well-maintained machine can last significantly longer, with reports indicating that proper care can extend its lifespan by up to 30%. Regular maintenance activities such as cleaning the print heads, checking the alignment, and ensuring that the ink system is functioning properly contribute to avoiding costly repairs and prolonged downtime in your operations. Additionally, lubricating the moving parts is crucial, as it reduces friction and wear, ultimately optimizing performance.

Furthermore, the environment in which the machine operates plays a pivotal role in its upkeep. Humidity and temperature levels can affect print quality and the integrity of the machine components. Ideally, operating your design machine in a climate-controlled setting can reduce the risk of damage caused by extreme conditions. According to the International Journal of Engineering Research, maintaining stable environmental conditions reduces malfunction rates by approximately 15%. By implementing these maintenance practices and considering environmental factors, you can ensure not only the machine's durability but also the quality of the custom apparel produced.