In the evolving world of screen printing, professionals face new challenges daily. Choosing the right screen printing machine is crucial for success. As noted by industry expert John Smith, "The right equipment can transform your printing process." This rings true as technology advances.

The screen printing screen printer industry demands innovation. Each machine offers unique features that can enhance workflow and quality. However, professionals often encounter difficulties in navigating these options. Not every machine will meet their specific needs, which can lead to frustration.

Understanding the top choices available is vital for any serious printer. The market is filled with options, each with its strengths and weaknesses. It is essential to reflect on what works best for individual situations. The journey to finding the ideal screen printing screen printer is not always straightforward, but it is worth the effort.

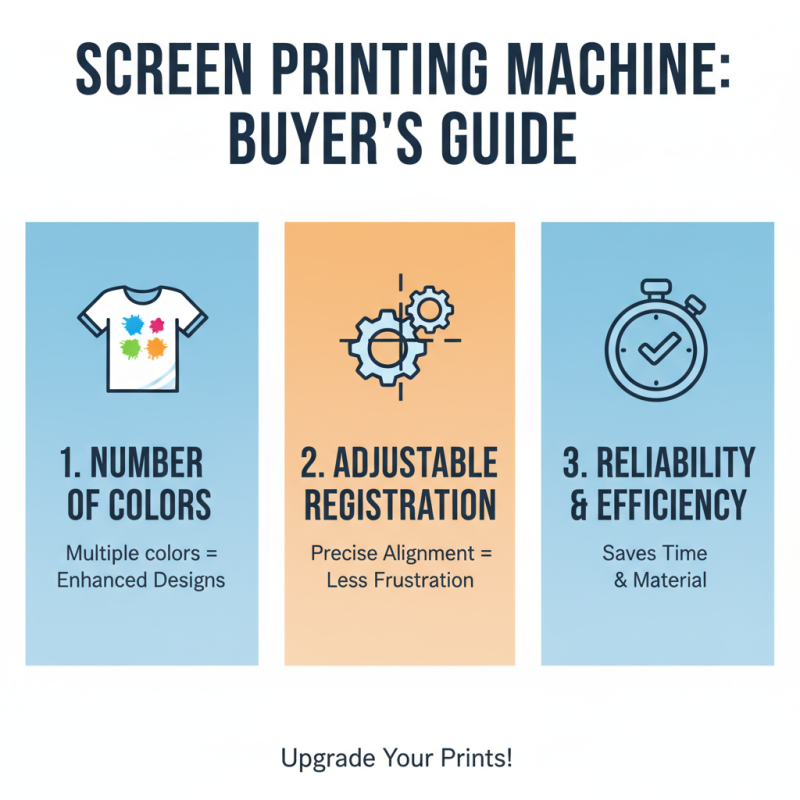

When selecting a screen printing machine, consider several key features. The number of colors it can print is crucial. Machines that handle multiple colors can enhance the quality of your designs. Look for models with adjustable registration systems. This detail allows for precise alignment of different colors. Users often struggle with registration issues. Having a reliable system can save time and frustration.

The printing speed also matters. A faster machine can increase productivity but may compromise quality. Balancing speed and quality is essential. Another important feature is the size of the printing area. Ensure it fits the materials you intend to use. Many machines have limited sizes, which can restrict creativity. Don’t overlook the ease of use. If a machine is too complicated, it may deter beginners.

Lastly, consider the durability of the machine. Investing in a robust model can minimize future costs. Frequent repairs or replacements can be frustrating. Take time to research and reflect on your needs. Every shop has unique requirements. Finding the right machine might take some effort and experimentation.

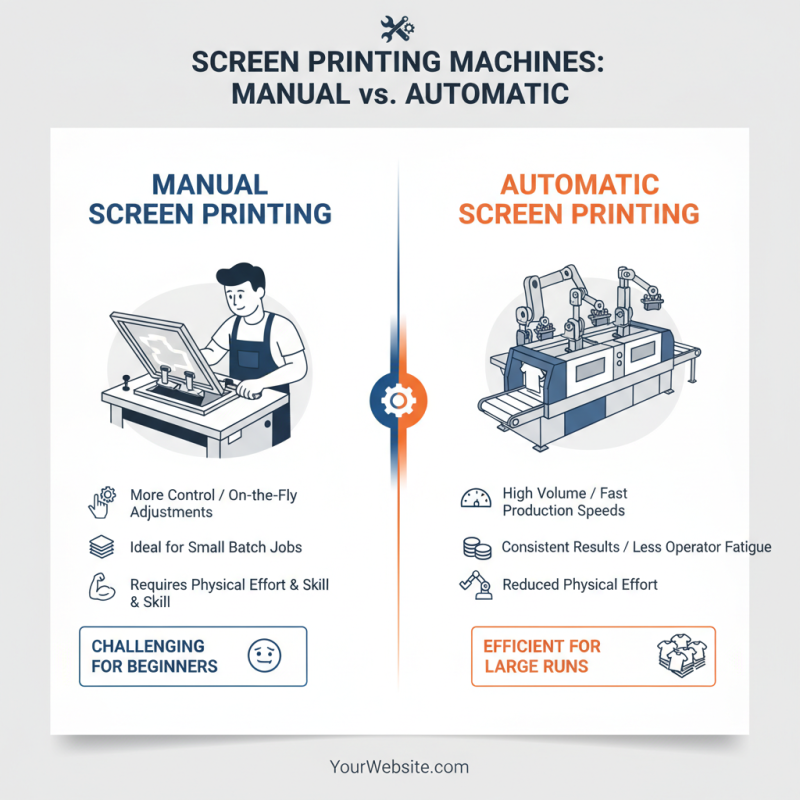

When deciding between manual and automatic screen printing machines, it's important to consider your production needs. Manual machines offer more control over the printing process. They allow for adjustments on the fly, making them ideal for small batch jobs. Yet, they require more physical effort and skill. Operators must ensure even pressure and alignment, which can be challenging for beginners.

Automatic machines, on the other hand, provide speed and consistency in high-volume production. They can print multiple colors seamlessly, reducing labor costs over time. However, they come with a higher initial investment and maintenance requirements. You might find the setup time can be frustrating. It's crucial to set up the machine correctly to avoid misprints.

Ultimately, the choice depends on your specific requirements. If you value flexibility and control, a manual machine might be your best bet. For efficiency and scalability, an automatic printer is likely the way to go. Balancing both options is key to optimizing your workflow and resources.

Innovative technologies are transforming screen printing machines in 2026. These advancements enhance efficiency and quality. A notable trend is the rise of automated setups. These machines reduce manual labor and speed up production. With faster printing speeds, businesses can meet growing demands. However, automation has its challenges. Technicians need to adapt and learn new skills. Some may struggle with this transition.

Another innovation is improved ink formulations. New eco-friendly inks are gaining popularity. These inks offer vibrant colors without harming the environment. They also provide better adhesion and durability. Yet, experimenting with these inks can be tricky. Manufacturers face a learning curve in optimizing their printing processes. Adjustments may be required to achieve the best results.

Digital integration is also a game-changer. Many screen printing machines now feature advanced software. This software allows for precise design manipulation and monitoring. But not all operators are tech-savvy. Some may find it difficult to fully utilize these systems. Striking a balance between traditional techniques and modern technology is crucial for success. Embracing change is essential, yet it can be overwhelming at times.

When investing in screen printing machines, cost is a critical factor. According to industry reports, professional screen printing machines range from $5,000 to $30,000. This variance depends on factors like machinery type and features. For example, automatic machines are more expensive but offer higher productivity. Manual machines are more affordable but require more labor.

A recent survey indicated that 70% of professionals prefer machines with user-friendly interfaces. This trend reveals a shift toward efficiency and ease of use. Professional-grade machines often come with additional features, like multi-color capability, which increase initial costs but can lead to higher profits. Analyze your business needs against these costs for the best results.

Tips: Consider total cost of ownership. Maintenance and operational costs can add up. Look for machines with lower maintenance needs. Evaluate financing options if cash flow is an issue. Small mistakes can lead to significant expenses. Always keep track of your budget to avoid overspending. Quality should not be compromised for price.

Maintaining screen printing equipment is crucial for longevity and performance. Regular cleaning after each use helps prevent ink buildup. A dirty screen can lead to poor quality prints. It's important to rinse screens immediately after finishing a job. This small step can save time and money on replacements.

Lubrication is another key aspect. Bearings and moving parts should be lubricated periodically to ensure smooth operation. Lack of lubrication can result in wear and even breakdown of components. Remember, neglecting this can lead to costly repairs or downtime.

Calibration of your screen printing machine should not be overlooked. It needs regular checks to maintain accuracy. Even slight misalignments may cause printing errors. Spend time checking alignment and adjusting as necessary. These routine maintenance tasks can be easy to overlook, but they are essential for efficient production.

This chart displays the performance ratings of the top 10 screen printing machines for professionals in 2026. The ratings, given out of 10, highlight the efficiency and reliability of each model, helping professionals make informed choices for their printing needs.