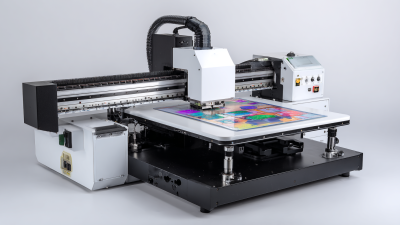

In today’s competitive market, a Clothing Printing Machine can significantly impact your business’s efficiency. Selecting the right machine influences costs, output quality, and turnaround times. With advancements in technology, these machines are more versatile and user-friendly than ever.

Businesses face many challenges when it comes to printing. Many struggle with outdated equipment that can't keep up with current demands. However, investing in modern printing solutions unlocks new potential. You can explore various options that suit different needs. For example, some machines excel in vibrant color reproduction, while others focus on speed.

The journey to enhancing productivity is not without its hurdles. Choosing the best Clothing Printing Machine requires understanding your specific requirements. Don't rush into decisions; take time to assess features and performance. It’s crucial to evaluate how these machines can directly benefit your workflow.

Clothing printing machines are essential in modern textile production. They allow businesses to create customized designs quickly and efficiently. According to a recent industry report, the global digital textile printing market is expected to reach $5 billion by 2025. This growth shows the increasing demand for personalized clothing. Companies can serve niche markets better with effective printing technology.

Efficiency plays a vital role in productivity. Machines that can print multiple colors in one go save time. Some machines, however, have a steep learning curve. This can frustrate operators. Training is necessary but can be time-consuming. An investment in high-quality equipment upfront may lead to long-term gains, but it can also strain small businesses financially.

Waste management remains a challenge in this field. Ink spills and fabric scraps can offset the benefits of modernization. Improving waste handling processes is essential to maintaining sustainability. Research indicates that 30% of materials are wasted during printing. This inefficiency highlights the need for continuous improvement. Investing in better technology may not always solve these problems. It’s a complex industry where adaptability is key.

When selecting clothing printing machines, key features can significantly impact productivity. Look for machines that offer versatility in printing methods. Some machines support both DTG (Direct to Garment) and screen printing. This allows you to handle different orders with ease. Additionally, check the maximum print size. A larger print area can expand your creative options.

Speed is another crucial factor. Machines that can print quickly help meet tight deadlines. However, it's essential to balance speed with quality. Fast machines might compromise detail. It's worth evaluating print resolution as well. A resolution of 1200 dpi or higher usually ensures crisp and vibrant designs. Also, consider the ease of use. Intuitive interfaces can reduce the learning curve for staff.

Don't forget about maintenance requirements. Some machines require regular servicing, which can add cost and downtime. Review customer feedback to gauge reliability. Many businesses face challenges with their initial choices. Reflecting on these experiences can guide you toward better decisions. Sometimes, investing in a more forgiving machine pays off, especially for beginners.

This chart illustrates the production speed of various clothing printing machines. The data reflects how many items can be printed per hour using different printing technologies. Understanding the capabilities of these machines can help businesses enhance their productivity effectively.

Choosing the right clothing printing machine is crucial for any business. These machines can greatly improve productivity and quality. When selecting a model, consider its print speed, resolution, and ease of use. Each machine has unique specifications that can cater to different needs. Some are great for small runs, while others are better for large-scale production.

One common issue is the initial setup. Many machines require a learning curve. It may take time to learn the software and operations. Test runs are essential before committing to large orders. Pay attention to color accuracy. Sometimes, machines produce unexpected results. Regular maintenance is key to avoiding breakdowns. Chemicals used for cleaning can be harsh, so work in a well-ventilated space.

Look into additional features like mobile connectivity or online ordering systems. These can streamline operations. However, integration can be a challenge. Not all devices work smoothly together. Research thoroughly before making a decision. Balancing cost and features can be daunting. Focus on long-term benefits. A reliable machine is an investment in your brand's future.

| Machine Model | Printing Technology | Max Print Size (inches) | Print Speed (sq ft/hr) | Price Range (USD) |

|---|---|---|---|---|

| Model A | DTG | 14 x 20 | 300 | $15,000 - $20,000 |

| Model B | Screen Printing | 20 x 28 | 600 | $10,000 - $15,000 |

| Model C | Sublimation | 16 x 24 | 500 | $12,000 - $18,000 |

| Model D | Vinyl Cutter | Max width 24 | N/A | $2,000 - $5,000 |

| Model E | Direct to Film | 13 x 19 | 250 | $8,000 - $12,000 |

| Model F | Laser Printing | 11 x 17 | 400 | $7,000 - $11,000 |

| Model G | Hybrid Inkjet | 18 x 24 | 350 | $9,000 - $14,000 |

| Model H | Embroidery | Max 12 x 12 | 100 | $5,000 - $9,000 |

| Model I | Cold Transfer | 24 x 30 | 200 | $6,000 - $8,000 |

| Model J | 3D Printing | 8 x 10 | 30 | $3,000 - $7,000 |

When it comes to choosing the right clothing printing machine, understanding performance and efficiency is crucial. Several key factors can greatly influence your business's output. Many machines vary in speed, print quality, and maintenance needs. Some machines deliver vibrant prints but may require frequent servicing. Others offer solid performance, but fall short on print details. Reflect on your business priorities before making a decision.

One common tip is to always test a machine before committing. Request samples to gauge quality. Evaluate how quickly a machine can produce these samples. Speed matters, but quality cannot be compromised. You might find a balance between these two.

Consider the ongoing costs, too. Some machines have lower initial prices but higher ink or maintenance costs. It’s easy to overlook these details. A less expensive machine could end up being more costly in the long run. Keep track of expenses if you want to maximize productivity. Look beyond the initial price tag; think about what this investment means for your future.

Investing in the right printing machines can significantly boost your business productivity. High-quality printing equipment can produce vibrant designs and intricate details. This helps capture customer attention. Having reliable machines minimizes downtime and enhances workflow. Regular maintenance is essential to prevent unexpected failures. Neglecting this can lead to delays and lost revenue.

Different printing technologies offer various benefits. Direct-to-garment printers excel in detailed designs. They work well for small runs. However, for bulk orders, screen printing machines are often more efficient. Each type has its strengths and weaknesses. Understanding your specific needs is crucial. It's important to evaluate your business model and demand before making a choice. Adapting to market trends can influence equipment decisions.

Investing in training for your staff can maximize machine efficiency. Well-trained employees can operate machines more effectively. This reduces errors and increases output quality. However, it's vital to assess skills periodically. Even experienced operators need updates and refreshers on new models. The right machine paired with skilled workers can transform your printing process.