The T Shirt Printing Printer Machine is a revolutionary device in the world of custom apparel. It allows users to print unique designs directly onto fabric. This technology has transformed how businesses and individuals create personalized clothing.

With this machine, creativity knows no bounds. You can print vibrant colors and intricate designs that were once difficult to achieve. However, it requires proper setup and maintenance to function effectively. Many users overlook these aspects, which can lead to unsatisfactory results.

This printer machine also challenges traditional printing methods. Although it offers convenience, some people struggle with quality control. Finding the right settings for different fabrics can be tricky. These factors make the T Shirt Printing Printer Machine both exciting and demanding for designers and entrepreneurs alike.

A T-shirt printing printer machine is a modern tool for custom clothing. It allows users to print designs directly onto fabric. This technology has gained popularity due to its efficiency and ease of use. Many businesses now rely on it for creating personalized apparel. Industry reports indicate that the global digital textile printing market was valued at around $3 billion in 2021 and is expected to grow significantly.

These machines work through various methods, including direct-to-garment (DTG) and heat transfer printing. DTG uses inkjet technology to apply water-based inks directly onto the fabric. This method is great for intricate designs and allows for vibrant colors. In contrast, heat transfer printing involves applying a design onto a material using heat. It's simpler but may not be as durable as DTG.

Tip: Always ensure your printer is compatible with the fabric type you plan to use. Additionally, consider the longevity of designs. Some prints may fade over time if not done correctly. Understanding these nuances is crucial for quality output. Remember, not all methods yield the same results; some experimentation may be necessary to find the best fit for your needs.

T-shirt printing machines use various techniques to transfer designs onto fabric. Each method has its unique process and outcomes. Some popular techniques include screen printing, direct-to-garment printing, and heat transfer printing.

Screen printing is a classic technique. It involves creating a stencil, or screen, and pushing ink through it onto the shirt. This method is reliable but can be costly for small batches. The colors are vibrant, yet the setup time can be lengthy.

Direct-to-garment (DTG) printing is a newer technique. It works like an inkjet printer, spraying ink directly onto the shirt. This allows for complex images and color gradients. However, it may not be the best for large orders. The longevity of the prints can vary too.

Heat transfer printing uses heat to apply designs from a special paper onto fabric. It’s versatile and easier for small runs. But, the prints can feel stiff.

When choosing a technique, think about the design complexity, batch size, and fabric type.

Tips: Always test print on scrap fabric first. This helps avoid costly mistakes. Consider the long-term durability of each technique. Consulting with experts can streamline your process. Test your designs for color accuracy.

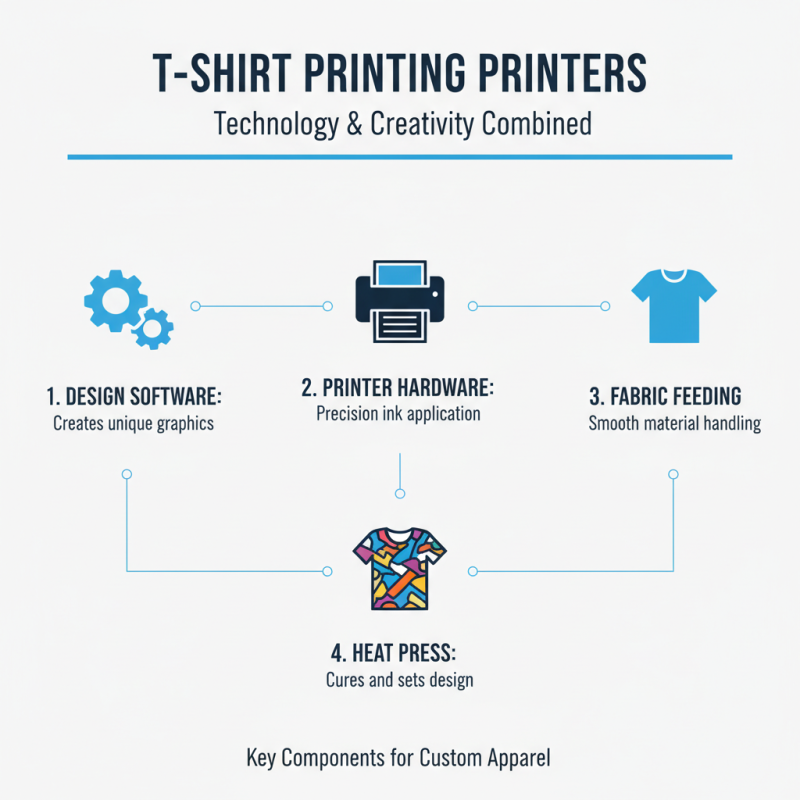

T-shirt printing printer machines are fascinating devices. They combine technology and creativity to produce unique designs on fabric. Key components play a significant role in their operation.

One essential part is the print head. It transfers ink onto the shirt, ensuring high-quality images. The print head's precision is crucial for detailed artwork. Sometimes, alignment issues occur, leading to misprints. Regular maintenance of the print head can help resolve these problems.

Another important component is the ink system. Different types of ink can be used, including water-based and solvent-based options. Each has its own advantages and challenges. Water-based inks are eco-friendly but may require more care during printing. Solvent-based inks are vibrant but can pose health risks. Understanding these inks is vital for successful printing. Problems can arise if the wrong ink is selected for the project. Consistent training and knowledge are important for operators.

T-shirt printing machines are fascinating tools. They bring designs to life with precision and quality. A high-quality print requires the right balance of ink, pressure, and heat. These machines often use several printing techniques, like direct-to-garment (DTG) or screen printing. Each method offers unique advantages, though DTG is gaining popularity for its detail.

The process begins with preparing the artwork. Designers must ensure the resolution is high enough for clarity. Sometimes, this doesn't go as planned; blurry images can result in disappointment. Once everything is set, the machine applies ink layer by layer. The right temperature is crucial. Too low, and the ink won't bond well. Too high, and it might smear.

Quality control becomes vital at this stage. Operators often need to check for inconsistencies. An uneven print can spoil a batch of shirts. Attention to detail is essential; every shirt tells a story. How well it is told often reflects the operator's skills and the technology used. So, while machines enhance efficiency, human oversight remains key.

The T-shirt printing industry is dynamically evolving. Recent trends indicate a growing demand for customized apparel. Consumers increasingly seek unique designs and personalized expressions. This shift has prompted manufacturers to adopt advanced printing technologies. These include direct-to-garment (DTG) printing, which offers detailed prints.

As the market expands, the competition becomes fiercer. New players enter the field, driven by easy access to printing equipment. While this creates opportunities, it also challenges existing businesses to innovate. Environmental concerns are shaping preferences, too. Eco-friendly printing solutions are becoming essential. Brands and consumers alike are more conscious of sustainability.

Despite the positive growth, challenges persist. Quality control can be inconsistent, leading to unsatisfactory products. Trained staff is often needed, which can inflate operational costs. Not every design translates perfectly onto fabric. There can be issues with color fidelity and durability. Businesses must continuously evaluate their methods and adapt to stay relevant in this fast-paced market.