When it comes to custom apparel, finding the right method of printing is crucial for achieving the best results. Among the various techniques available, "Printer On Shirts" has emerged as a popular choice for many individuals and businesses alike. This printing method combines precision and vibrancy, allowing for intricate designs and vivid colors that truly bring custom shirts to life. Whether you are looking to promote a brand, commemorate a special event, or simply express your personal style, the benefits of using Printer On Shirts are undeniable.

One of the standout features of Printer On Shirts is its versatility. This technique accommodates various fabric types, ensuring that your chosen material can display the artwork effectively. Moreover, the durability of the print ensures that your designs will last through many washes and wears, making it a cost-effective solution for long-term use. Additionally, the ability to easily customize each shirt means that you can cater to individual preferences, which is especially beneficial for team events or personalized gifts.

Furthermore, with advancements in printing technology, the process has become more accessible than ever before. Whether you are a small business owner looking to create branded merchandise or an individual wanting to make a statement with unique designs, Printer On Shirts allows for both creative freedom and professional-quality output. In this article, we will explore the various advantages and considerations of choosing Printer On Shirts for your custom apparel needs, guiding you towards making an informed decision that meets your specific requirements.

When it comes to customizing apparel,

printer-on shirts offer a unique blend of creativity and practicality that sets them apart from traditional methods.

One of the most significant benefits of using printer on shirts is the ability to achieve

intricate and vibrant designs

that can showcase detailed artwork or personalized messages. This printing method allows for

full-color images, gradients, and complex patterns, making it an ideal choice for those who want to make a bold statement with their clothing.

Another advantage of printer on shirts is the efficiency and speed of production.

Unlike other customization techniques that may require lengthy setup times or minimum order quantities,

printer-on shirts can be produced quickly in smaller batches.

This flexibility is particularly beneficial for events, promotions, or small businesses looking to test designs without committing to large inventories.

Additionally, the durability of printed designs ensures that the apparel holds up well over time,

offering longevity without compromising on visual appeal.

This combination of quality, speed, and versatility makes printer-on shirts a compelling option for anyone in need of

custom apparel.

When considering printer on shirts for custom apparel needs, it's essential to focus on the types of materials that are most suitable for this printing technique. Fabrics like cotton, polyester, and blends are widely favored due to their compatibility with various printing methods. According to a recent industry report, 60% of custom apparel consumers prefer cotton shirts for their breathability and comfort, which makes them ideal for both casual and promotional wear.

Polyester, on the other hand, offers vibrancy in color and durability, making it suitable for athletic apparel. Recent data indicates that 70% of sportswear brands opt for polyester to achieve long-lasting prints without fading. Blended fabrics, combining the benefits of both cotton and polyester, are also popular, providing comfort along with moisture-wicking properties.

Tips for selecting the right material include testing fabric samples before making bulk orders, as variations in weave and finish can impact print quality. Additionally, consider the intended use of the apparel; for example, heavier fabrics may be more durable for work uniforms, while lighter materials are preferable for fashion-forward designs. Ensure that the chosen material aligns with your brand’s message for cohesive representation in your custom apparel.

When considering custom apparel, the design options available for printer on shirts are vast and increasingly sophisticated. According to a recent report by MarketsandMarkets, the global custom apparel market is anticipated to reach USD 10 billion by 2025, highlighting a growing demand for personalized clothing solutions. This trend is largely driven by the rise of e-commerce and a shift towards unique, self-expressive fashion choices among consumers. Whether it’s for promotional events, team uniforms, or individual expression, printer on shirts provide a flexible canvas for creativity.

One of the most appealing aspects of printer on shirts is the variety of printing techniques that can be used to achieve striking designs. Techniques like Direct-to-Garment (DTG) printing, which allows for high-resolution images and complex color gradients, are gaining popularity. According to a statistic from IBISWorld, the DTG printing industry has seen a growth rate of 25% over the last five years due to its efficiency and quality, making it a preferred choice for custom designs. Furthermore, options such as screen printing and heat transfer allow for bold, vibrant creations, ensuring that even small-scale orders can result in eye-catching apparel. Whether you envision intricate designs, vibrant graphics, or simple logos, the adaptability of printer on shirts makes them an ideal choice for any custom apparel need.

When considering custom apparel options, the cost-effectiveness of printer on shirts stands out as a significant factor. Recent reports indicate that direct-to-garment (DTG) printing, a popular method for applying designs directly onto fabric, typically incurs lower setup costs compared to traditional screen printing. Screen printing often requires expensive screens and a larger minimum order volume, making it less accessible for small businesses or individuals looking for personalized items. Research from the Apparel Printing Association highlights that DTG printing can be up to 30% more economical for small batches, making it an attractive choice for custom apparel needs.

In addition to reduced initial costs, printer on shirts allows for greater design flexibility without sacrificing quality. Digital printing technology has advanced rapidly, allowing for high-resolution images and intricate designs to be printed directly onto fabrics. This capability reduces waste, as there’s less need to overproduce items to meet minimum orders. According to a survey by the Custom Apparel Association, 65% of customers favor methods that offer quicker turnaround times without compromising design quality, which DTG printing effectively provides. This makes printer on shirts not only a budget-friendly option but also a practical choice for meeting diverse consumer demands in today’s fast-paced market.

| Method | Setup Cost | Cost Per Shirt | Turnaround Time | Best Use Case |

|---|---|---|---|---|

| Screen Printing | $50 | $5.00 | 5-7 days | Large Quantity Orders |

| Heat Transfer | $20 | $7.50 | 3-5 days | Small Batch Orders |

| Direct-to-Garment (DTG) | $30 | $10.00 | 2-3 days | Highly Detailed Designs |

| Printer On Shirts | $10 | $4.00 | 1-2 days | Custom and On-Demand |

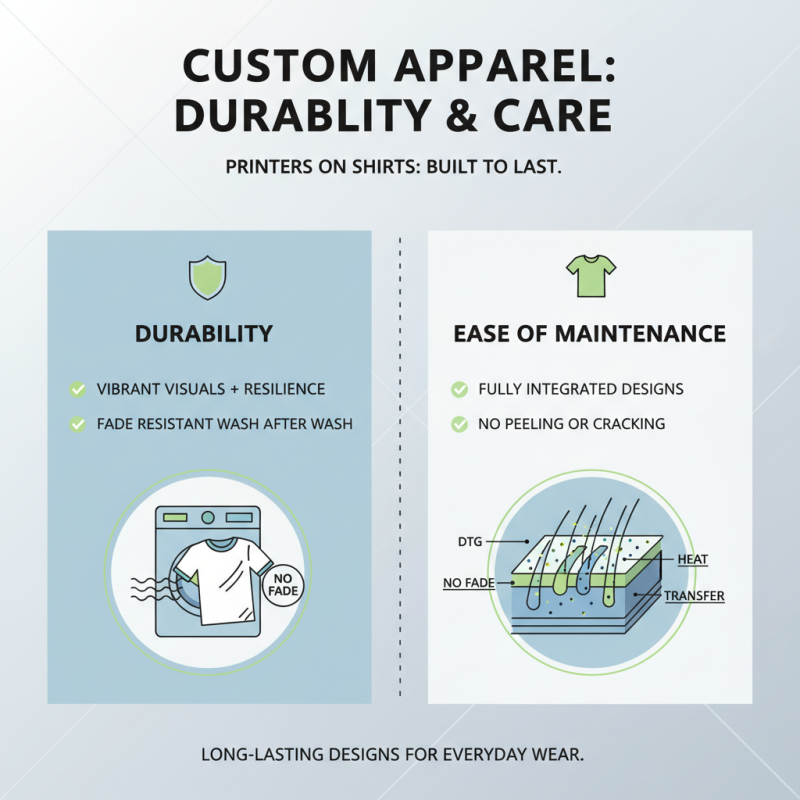

When it comes to custom apparel, durability and ease of maintenance are key considerations for ensuring the longevity of your designs. Printer on shirts offers a unique combination of vibrant visuals and resilience, making them suitable for a variety of occasions and wearers. The printing techniques used, such as direct-to-garment (DTG) or heat transfer, allow every design to be fully integrated into the fabric rather than simply layered on top. As a result, print durability is enhanced, resisting fading even after repeated washes, which is crucial for apparel that sees frequent use.

Maintaining printer on shirts is straightforward and hassle-free. Most designs withstand regular machine washing without losing quality, though it is advisable to follow care instructions to maximize lifespan. Using cold water and avoiding bleach can help keep the shirt looking new longer. Additionally, these shirts typically dry quickly, reducing the risk of lingering moisture that can lead to odors or mildew. The ease of care not only makes them an attractive option for individuals but also for businesses looking for uniform solutions, as they require less upkeep over time. This makes printer on shirts a reliable choice for high-quality custom apparel that stands the test of time with both function and flair.