The evolution of Silk Screen Printer technology is poised to revolutionize various industries, from apparel manufacturing to electronics. With the global screen printing market projected to reach $5.4 billion by 2025, according to a report by Research and Markets, the demand for high-quality, efficient printing solutions is greater than ever. Advances in automation, eco-friendly inks, and hybrid printing technologies are addressing long-standing challenges such as print consistency and speed. Furthermore, the rise of personalized and on-demand printing is reshaping consumer expectations and operational strategies across sectors. As industries increasingly adopt these next-generation Silk Screen Printers, understanding their impact on productivity and sustainability will be crucial for businesses aiming to stay competitive in a rapidly changing marketplace.

Silk screen printing, a technique that dates back to ancient times, has undergone significant transformations over the centuries. Originating in China more than a thousand years ago, this method initially used silk fabric stretched over a frame to transfer ink onto textiles. As merchants traveled the Silk Road, they brought this technique to various cultures, leading to a blend of artistic styles and printing methods. By the early 20th century, silk screen printing gained popularity in the United States, particularly in the realm of commercial printing and advertising.

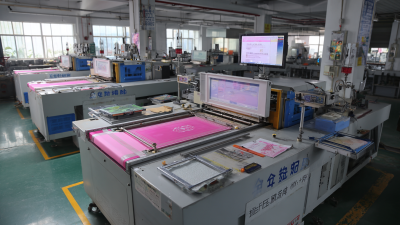

The evolution of silk screen printing technology has been marked by the introduction of synthetic fabrics and modern inks, enhancing both the quality and durability of printed materials. The advent of automated machines has further revolutionized the process, allowing for faster production times and greater precision. This advancement has made silk screen printing more accessible to various industries, from fashion to packaging, paving the way for innovative applications. Today, we see screen printing not just as a production method but as a vibrant form of artistic expression, reflecting the ongoing evolution of this timeless craft.

The realm of silk screen printing is poised for a significant transformation fueled by innovative technologies. Recent advancements are not only enhancing quality and efficiency but are also redefining the very essence of the industry. For instance, companies are increasingly integrating artificial intelligence and automation into their processes, enabling more precise color matching and reduced waste. This shift towards smart technology is making silk screen printing more adaptable, allowing businesses to respond quickly to market trends and consumer demands.

Moreover, sustainability has become a cornerstone in modern printing practices. Innovations such as eco-friendly inks and recyclable materials are gaining traction, reflecting the industry's commitment to environmental stewardship. As today’s consumers become more eco-conscious, these advancements are vital for maintaining competitiveness while reducing ecological footprints. Companies that embrace these technologies can expect to not only improve operational effectiveness but also align themselves with the growing preference for sustainable practices in various industries. In an era where agility and responsibility are paramount, the next generation of silk screen printing technology promises to elevate the entire sector.

The emergence of next-generation silk screen printing technology is revolutionizing several key industries, driving efficiency and innovation. One of the most impacted sectors is the fashion industry, where brands are adopting advanced silk screen printers to create intricate designs with unparalleled precision. This technology allows for the use of eco-friendly inks and materials, aligning with the growing consumer demand for sustainable practices. As a result, fashion companies can produce vibrant, high-quality garments while minimizing their environmental footprint.

In addition to fashion, the packaging industry is experiencing a transformation through next-gen silk screen printing. This technology enables manufacturers to print complex graphics and branding on various surfaces, enhancing product visibility and consumer engagement. Beyond aesthetics, the durability of the prints ensures that packages can withstand the rigors of transport and storage without losing their appeal. Consequently, businesses in this field are not only improving their operational efficiency but also elevating the overall customer experience. The ripple effects of this technology are undoubtedly setting new standards across industries, redefining how products are developed and marketed.

The advancement of silk screen printing technology has significantly shifted towards sustainability, leading to eco-friendly practices that resonate across various industries. Recent studies highlight a growing awareness of environmental impacts, with initiatives focusing on the incorporation of sustainable materials in production processes. For instance, a life cycle assessment approach in printed sensor technology seeks to minimize environmental footprints, showcasing how innovation can align with sustainable development goals.

Tips for adopting eco-friendly practices include prioritizing biodegradable inks and sourcing organic fabrics. Businesses can enhance their sustainability efforts by implementing efficient ink management systems, which not only improve printing efficiency but also significantly reduce waste and environmental impact. According to data, the screen printing inks market is expected to grow from $4.83 billion in 2025 to $6.37 billion by 2034, indicating a robust demand for sustainable solutions in the printing industry.

Moreover, the integration of advanced materials such as dopamine-functionalized activated carbon composites into screen printing has propelled the development of sustainable energy solutions. This trend reflects the ongoing commitment within the industry to leverage innovative technologies while fulfilling environmental responsibilities, creating a more sustainable future for fashion and beyond.

As we look to the future of silk screen printer technology, several trends are set to reshape how industries utilize this age-old printing method. One major shift is the adoption of digital integration. Combining digital printing techniques with traditional silk screen methods allows for greater precision, quicker turnaround times, and the ability to produce intricate designs that were once difficult to achieve. This fusion not only meets the booming demand for customization but also enhances production efficiency, making silk screen technology more relevant than ever.

Tip: When considering a transition to digital silk screening, explore software that offers real-time printing solutions. This can improve workflow and minimize the learning curve for your team.

Another noteworthy trend is the emphasis on sustainability. With a growing awareness of environmental issues, manufacturers are developing eco-friendly inks and materials. This shift not only aligns with consumer values but also helps companies reduce their carbon footprint. Brands that adopt these greener technologies often see an increase in consumer loyalty.

Tip: Invest in training and resources that focus on sustainable practices in silk screening. Keeping your team informed will help your business stay ahead in an environmentally-conscious market.