In today's competitive manufacturing landscape, maximizing efficiency is crucial for staying ahead of the curve. The Oval Printing Machine has emerged as a vital asset in many production lines, streamlining processes and reducing waste. According to a recent report by Smithers Pira, the global digital printing market is projected to reach $29.5 billion by 2025, indicating a robust shift towards automated and efficient printing technologies. This trend underscores the importance of investing in advanced machinery like the Oval Printing Machine, which not only enhances speed and precision but also optimizes resource allocation. With its ability to handle diverse printing needs and improve turnaround times, leveraging the capabilities of the Oval Printing Machine can lead to significant cost savings and increased productivity, positioning businesses for success in an evolving market.

In today's competitive manufacturing landscape, maximizing efficiency is crucial for staying ahead of the curve. The Oval Printing Machine has emerged as a vital asset in many production lines, streamlining processes and reducing waste. According to a recent report by Smithers Pira, the global digital printing market is projected to reach $29.5 billion by 2025, indicating a robust shift towards automated and efficient printing technologies. This trend underscores the importance of investing in advanced machinery like the Oval Printing Machine, which not only enhances speed and precision but also optimizes resource allocation. With its ability to handle diverse printing needs and improve turnaround times, leveraging the capabilities of the Oval Printing Machine can lead to significant cost savings and increased productivity, positioning businesses for success in an evolving market.

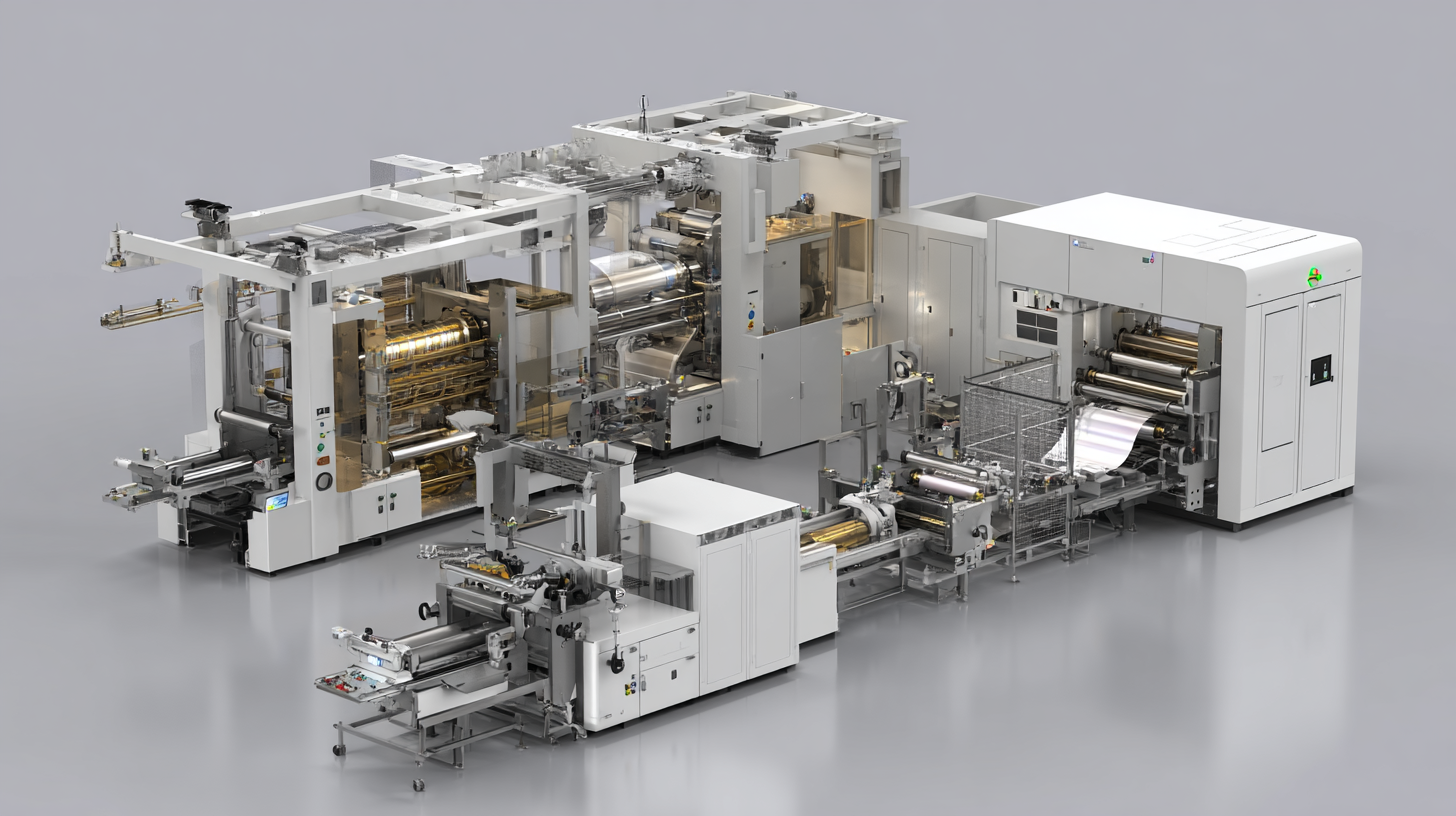

Oval printing machines are becoming increasingly vital in modern production lines, offering unique advantages that maximize efficiency. Understanding the fundamentals of these machines can significantly enhance the production process. Oval printing machines operate using a rotary screen printing method that allows for high-speed printing on various substrates. According to a recent industry report, the adoption of advanced printing technology, such as oval machines, has shown to increase throughput by up to 30%, which is crucial in meeting growing market demands.

Additionally, oval printing machines provide versatility, enabling the application of intricate designs and vibrant colors that traditional methods may struggle to achieve. This flexibility is illustrated by statistics indicating that companies employing oval printing technology have experienced a 25% reduction in material waste due to better ink usage and fewer misprints. As the printing industry continues to evolve, fully grasping the operational capabilities of oval printing machines can lead to significant improvements in efficiency and product quality, essential for staying competitive in today’s fast-paced market.

In the modern printing industry, maximizing efficiency is crucial for staying competitive, and oval printing machines are at the forefront of this transformation. These machines boast key features that significantly enhance productivity. For instance, their ability to print on various substrates allows for versatility in production, catering to different client needs without extensive setup modifications. Furthermore, the oval design optimizes ink distribution, ensuring even coverage and higher print quality, which can reduce waste and minimize errors during production.

To get the most out of your oval printing machine, consider implementing these tips:

To maximize the output of the oval printing machine, optimizing the setup is crucial. First, ensure that the machine’s alignment is precise. Misalignment can cause uneven ink distribution, leading to poor quality prints and wasted materials. Regularly check and adjust the registration settings, utilizing both manual and automatic adjustments as necessary. This attention to detail can significantly enhance print accuracy and reduce errors, ultimately boosting your production line’s efficiency.

Additionally, consider the workflow surrounding the oval printing machine. Streamlining the loading and unloading processes will minimize downtime. Implement a standardized operating procedure for staff to follow, ensuring that all team members are trained to use the machine effectively. Setting up an efficient inventory management system for inks and substrates can also prevent delays caused by running out of materials mid-production. By combining precise setup techniques with an organized workflow, you can significantly increase the output of your oval printing operations.

| Technique | Description | Expected Output Increase (%) | Setup Time (Minutes) |

|---|---|---|---|

| Optimal Ink Usage | Adjust ink flow to reduce waste without compromising quality. | 15% | 5 |

| Regular Maintenance | Schedule routine inspections and part replacements to minimize downtime. | 20% | 30 |

| Efficient Material Handling | Implement systems for quick loading and unloading of materials. | 10% | 15 |

| Staff Training | Conduct training sessions to improve operator skills and efficiency. | 25% | 60 |

| Workflow Optimization | Analyze and restructure workflow for smoother operation. | 30% | 45 |

Maintaining an Oval Printing Machine is crucial to ensuring its longevity and optimal performance within your production line. According to a report by the Printing Industries of America, routine maintenance can extend machinery life by up to 30%. Regular inspections and timely servicing are essential practices that not only mitigate the risk of breakdowns but also enhance print quality and operational efficiency. It is advisable to establish a maintenance schedule that includes daily checks, monthly cleanings, and annual professional servicing.

One of the best practices includes regularly calibrating the machine to maintain print accuracy and consistency. A study conducted by Smithers Pira indicates that equipment calibration can lead to a reduction in waste by 15%, further supporting cost-effectiveness in production. Additionally, using high-quality inks and substrates can minimize wear and tear on the machine components, thus contributing to its longevity.

Investing in staff training on machine operation and care can also play a significant role in reducing operational hiccups and maximizing efficiency. By integrating these maintenance best practices, production facilities can ensure their Oval Printing Machines operate at peak performance for years to come.

To maximize efficiency with the Oval Printing Machine, proper training of your team is crucial for effective operation and troubleshooting. Engaging employees through systematic training initiatives can significantly improve their skills and confidence in handling the machine, which in turn accelerates the production process. A well-structured training program not only covers the technical aspects of operating the printing machine but also emphasizes problem-solving strategies for common issues that may arise during production.

Moreover, fostering a culture of continuous learning within the organization helps in sustaining the knowledge acquired during training. Encouraging team members to share their experiences and insights can create an environment conducive to collaborative troubleshooting. This dynamic approach ensures that every team member feels valued and actively participates in the optimization of operations. As the landscape of production evolves, empowering employees with the right skills and knowledge becomes essential for maintaining a competitive edge in the market.