The silk screen printing machine has long been a staple in the textiles and graphics industries, renowned for its versatility and efficiency in producing vibrant images on various surfaces. According to a recent market research report by Smithers Pira, the global screen printing market is projected to reach $6.6 billion by 2024, driven by advancements in technology and an increasing demand for customized printing solutions. However, traditional silk screen printing machines come with their limitations, including high initial setup costs, labor intensity, and environmental concerns related to ink and waste. As businesses seek to innovate and streamline their production processes, exploring alternatives such as digital printing technologies, hybrid systems, and eco-friendly materials is essential. This guide aims to delve into these innovative solutions that can enhance operational efficiency while meeting the evolving demands of the market, ultimately providing a fresh perspective on silk screen printing in today’s competitive landscape.

In today’s fast-paced manufacturing environment, the demand for efficiency in screen printing has led to the exploration of innovative techniques that go beyond traditional silk screen printing machines. The industry is evolving, and businesses are eager to adopt methods that not only streamline production but also enhance quality. Digital printing technology has emerged as a viable alternative, allowing for quick adjustments and reduced setup times. With its ability to handle intricate designs and a variety of substrates, digital printing caters to the growing demand for custom and on-demand solutions.

Furthermore, eco-friendly practices are becoming increasingly important in screen printing. Techniques such as water-based inks and sustainable materials are not merely trends; they are essential responses to environmental concerns. Companies are implementing energy-efficient processes that minimize waste, contributing to a smaller carbon footprint. This shift not only meets the consumers' desire for sustainable products but also positions businesses as forward-thinking leaders in the industry. By embracing these innovative techniques, screen printing can evolve to meet modern demands while maintaining high standards of quality and sustainability.

As businesses continue to seek cost-effective production methods, the comparison between digital printing and traditional silk screen printing methods has become increasingly relevant. A recent report from Smithers Pira indicates that the digital printing market is forecasted to reach $29.2 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 11%. This surge in digital adoption is primarily attributed to its ability to reduce setup costs and be more flexible for short runs and customized prints, areas where traditional silk screen printing often struggles due to higher initial costs and longer lead times.

In terms of cost benefits, digital printing significantly reduces waste and labor costs. A 2022 study by the Printing Industries of America noted that while silk screen printing can be economical for bulk runs, the average cost per unit increases dramatically when production volumes drop below a certain threshold. On the other hand, digital printing allows for efficient production even in small quantities, typically resulting in a cost per unit that is 30% lower in short-run scenarios than its traditional counterpart. This flexibility not only helps businesses cater to changing market demands but also bolsters their sustainability efforts by minimizing excessive material use.

In recent years, the screen printing industry has seen a significant shift towards sustainability, with a growing demand for eco-friendly inks and materials that reduce environmental impact. According to a report by Smithers Pira, the global sustainable printing market is expected to reach $9.1 billion by 2025, driven by increasing consumer awareness and regulatory pressures. This transition is prompting many companies to explore alternatives to traditional plastisol inks, which are petroleum-based and harmful to the environment.

One of the most promising shifts in screen printing is the adoption of water-based inks, which are less toxic and easier to clean up. Water-based inks have been reported to emit 90% fewer volatile organic compounds (VOCs) than their solvent-based counterparts, making them a healthier choice for both printers and the environment. Furthermore, advances in biodegradable and soy-based inks are providing additional sustainable options that do not compromise on quality or vibrancy. Companies such as Eco-Label and Pantone are leading the charge in developing inks that meet stringent environmental standards, helping printers align their production processes with sustainability goals.

Additionally, the use of recycled and organic materials for screens and substrates is gaining traction. A study by the Sustainable Green Printing Partnership (SGP) revealed that the adoption of recycled substrates can reduce energy consumption by up to 45%. By integrating these sustainable practices into their operations, screen printers are not only addressing environmental concerns but also appealing to a market increasingly committed to ethical and eco-friendly purchasing decisions.

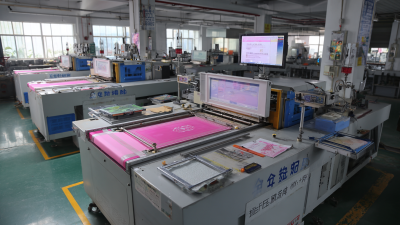

In the evolving landscape of screen printing, automation is playing a pivotal role in enhancing production speeds and efficiency. Traditional silk screen printing methods, while effective, often involve labor-intensive processes that can limit output and increase turnaround times. By integrating automated systems, businesses can streamline their operations, allowing for quicker setup times and minimal manual intervention. This shift not only reduces the risk of human error but also enables companies to meet higher demands without compromising on quality.

Moreover, innovative technologies such as computer-controlled printing heads and automated screen registration systems are revolutionizing the way screen printing is approached. These advanced solutions not only accelerate the production cycle but also provide the flexibility to execute intricate designs with precision. As a result, manufacturers can shift their focus from repetitive tasks to more creative aspects of production, ultimately leading to a more dynamic and responsive business model. Embracing automation isn't just about speed; it's about elevating the entire process of screen printing, making it more adaptive to the ever-changing market demands.

The future of screen printing is poised for remarkable transformation as technology integrates with traditional practices to create smarter, more efficient solutions. Innovations such as digital printing and hybrid systems are redefining production standards, elevating creativity while streamlining processes. This evolution promises to meet the growing demand for customization and personalization in various industries.

Tip: Embrace the latest printing technologies by investing in research and development. Collaborating with tech startups or industry leaders can provide insights into novel applications that enhance efficiency and open new market opportunities.

Furthermore, the trend towards automation in screen printing aligns with broader movements in other sectors, such as automotive and healthcare. The continuous push for integrated solutions emphasizes the significance of user-friendly interfaces and intelligent systems that foresee operational needs, improving overall productivity.

Tip: Stay ahead by continuously monitoring technological advancements. Implement training programs to upskill your workforce, ensuring they can adeptly navigate new systems and leverage machine learning for predictive maintenance and optimization.