Choosing the right screen printing machine is a critical decision for any business looking to thrive in the competitive world of custom printing. In recent years, the screen printing market has seen significant growth, with a report from Smithers Pira indicating an expected growth rate of 3.5% annually, reaching a value of over $5 billion by 2024. As the demand for high-quality, customizable products increases, businesses must carefully evaluate their needs and the capabilities of different screen printing machines.

Factors such as print quality, machine efficiency, and production volume can significantly impact your business's success. By understanding the nuances of screen printing technology and aligning them with your operational requirements, you can make an informed choice that enhances productivity while ensuring excellent results for your customers.

When it comes to choosing the right screen printing machine for your business, understanding the scale of your operations is crucial. Small businesses often prioritize versatility and affordability, needing machines that can handle a range of t-shirt designs while keeping initial costs low. According to industry reports, small-scale printers can benefit significantly from entry-level models that offer automatic features, enabling them to maximize production efficiency without overextending financially. A recent survey revealed that over 60% of small business owners cited equipment affordability as a top concern when starting their operations.

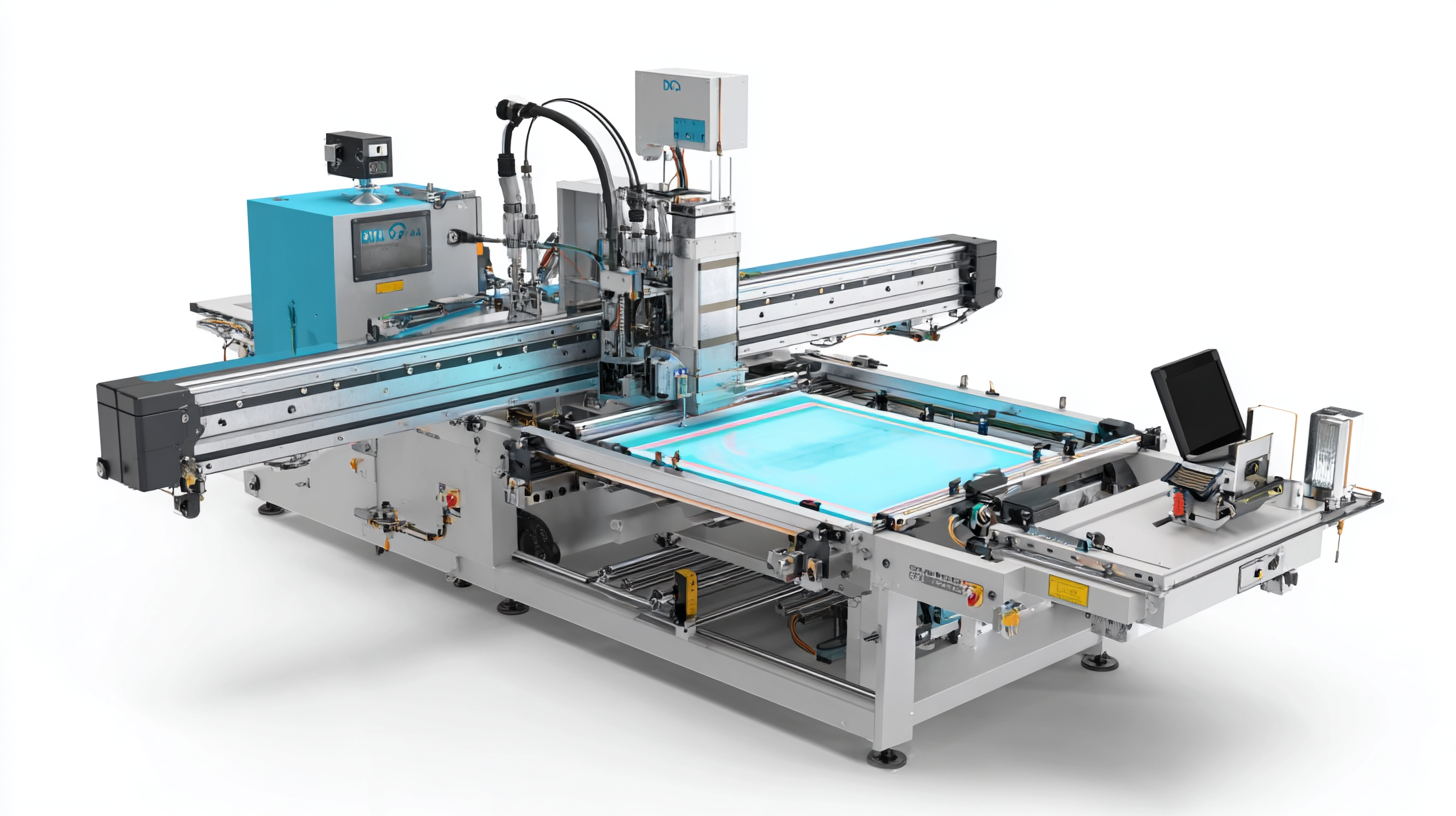

In contrast, larger businesses tend to focus on industrial-grade machines that offer high-volume output and advanced technology. These machines often come equipped with automated processes that can minimize labor costs and improve consistency across large batches. Economies of scale play a vital role here: for instance, large operations can achieve significant cost reductions estimated at 15-20% per unit due to their ability to purchase materials in bulk and streamline production lines. Such insights highlight that the choice of screen printing machinery should align not only with the current business size but also with long-term growth strategies.

When selecting a screen printing machine for your business, evaluating production volume is crucial. The output capacity of a machine directly impacts your ability to meet customer demands efficiently. If your business anticipates high-volume orders, investing in automatic screen printing machines would likely be beneficial. These machines can significantly increase output rates and reduce labor costs, allowing you to fulfill larger orders in shorter timeframes.

Conversely, if your business focuses on lower-volume jobs or maintains a boutique approach, a manual or semi-automatic machine might be more suitable. These models often have lower initial costs and offer greater flexibility for customization, making them ideal for smaller runs or intricate designs. Understanding your production needs and how they align with the capabilities of different machines will ensure you choose the right equipment to support your business growth effectively.

When assessing print quality in screen printing, two key factors come into play: DPI (dots per inch) and screen mesh count. DPI essentially measures the resolution of the printed image, directly influencing the clarity and detail of the final output. A higher DPI results in sharper images and smoother gradients, which is crucial for applications that demand high fidelity, such as fine art prints or intricate designs. Coupled with DPI is the screen mesh count, which refers to the number of threads per inch in a screen. A higher mesh count allows for finer details to be printed, making it ideal for more complex images or logos.

Recent advancements in screen printing technologies, particularly for textiles and innovative applications like solar cell metallization, emphasize the importance of these measurements. For instance, fine line screen printing techniques and simulations for metal electrode patterns show how crucial proper screen settings are for precise outputs. Additionally, the choice of ink and mesh can greatly impact the physical properties of printed materials, hence understanding and optimizing DPI and screen mesh count becomes essential for achieving the best results, whether for creating wearable electronics or traditional textile prints.

When selecting the right screen printing machine for your business, budget considerations extend beyond the initial purchase price. According to the Specialty Graphic Imaging Association (SGIA), the average cost of a quality screen printing machine can range from $5,000 to over $100,000, depending on features and capabilities. While lower-end machines may be appealing for startups with tight budgets, they often lack the longevity and efficiency necessary for scaling operations. Investing in a higher quality machine can lead to cost savings in the long run through reduced maintenance costs and increased production speeds.

Moreover, industry reports from Freedonia Group indicate that high-performance screen printing machinery can yield a return on investment (ROI) upwards of 30% over five years, primarily due to their enhanced output and reliability. When analyzing costs versus long-term investment, consider factors such as the production volume, the complexity of designs, and the versatility required for various substrates. By understanding these dynamics, businesses can better allocate their budgets to not only meet immediate needs but also to foster growth and adaptability in a competitive market.

| Machine Type | Initial Cost ($) | Maintenance Cost (Annual $) | Production Capacity (Items/Hour) | Estimated Lifespan (Years) | Total Cost of Ownership ($) |

|---|---|---|---|---|---|

| Manual Screen Printer | 2,500 | 300 | 30 | 10 | 5,300 |

| Automatic Screen Printer | 15,000 | 1,200 | 300 | 15 | 21,000 |

| Digital Screen Printer | 20,000 | 800 | 50 | 10 | 28,000 |

| Hybrid Screen Printer | 25,000 | 1,000 | 100 | 12 | 37,000 |

When selecting the ideal screen printing machine, understanding the technological features of digital versus manual options is paramount. Digital screen printing technology has gained significant traction in recent years, with the global digital textile printing market projected to reach $5.4 billion by 2027, reflecting a compound annual growth rate (CAGR) of 11.5% from 2020. This growth can be attributed to the advantages of digital processes, such as quicker setup times and the ability to produce complex designs with minimal waste, making it particularly appealing for businesses that prioritize efficiency and customization.

Moreover, innovations in digital technology are reshaping the landscape of printmaking. The integration of digital embellishment modules allows for enhanced design capabilities that can seamlessly merge traditional screen printing techniques with modern digital processes. For example, advancements like multi-pass inkjet embellishment enable printmakers to add textures and effects that were previously difficult to achieve. As reported, the flexibility and versatility of these technologies position them as valuable assets for businesses aiming to stay competitive in a rapidly evolving market. Embracing these digital printing solutions can lead to improved product offerings and meet diverse customer needs effectively.