In the ever-evolving world of printing technology, selecting the appropriate screen printing machine is crucial for businesses aiming to thrive in a competitive market. The global screen printing market was valued at approximately $4.9 billion in 2022 and is projected to reach $6.2 billion by 2030, growing at a CAGR of 3.6% from 2023 to 2030. This growth underscores the increasing demand for high-quality printing solutions across various sectors, including textiles, electronics, and promotional items. Choosing the right screen printing machine not only impacts production efficiency but also influences the quality of the final product, directly correlating with customer satisfaction and business profitability.

When embarking on the journey to select a screen printing machine, businesses must consider several factors, including production volume, print quality, and material compatibility. According to industry reports, businesses that invest in advanced screen printing technologies can achieve up to a 30% increase in production speed and a significant reduction in waste material. Moreover, with the rise of e-commerce and customized products, the ability to offer diverse printing options while maintaining cost-effectiveness has never been more critical. By carefully evaluating their specific needs against the capabilities of various screen printing machines, companies can position themselves effectively in the marketplace and enhance their operational success.

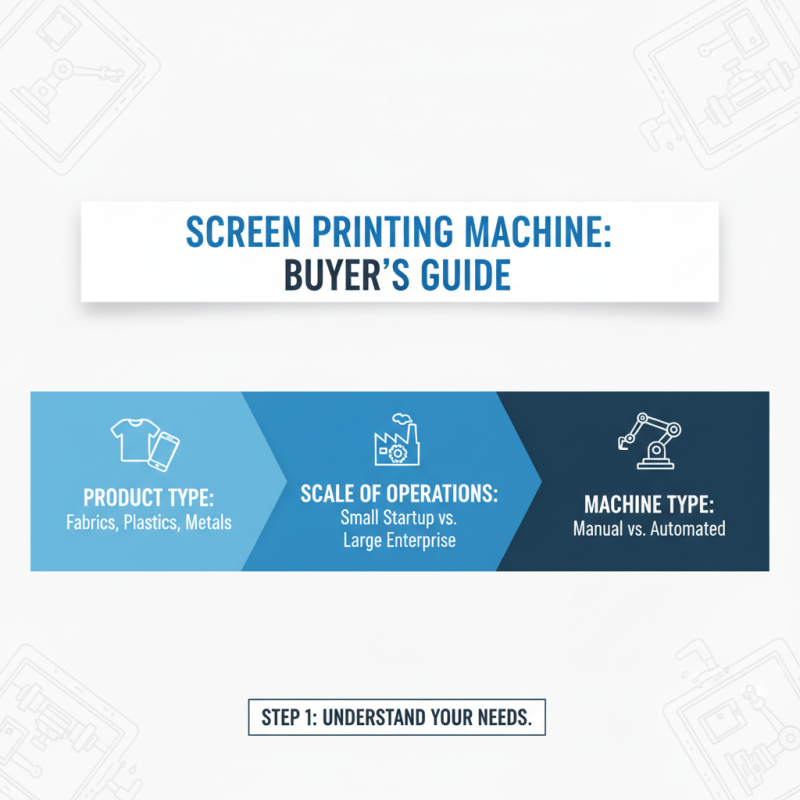

When embarking on the journey of acquiring a screen printing machine, the first step is to thoroughly understand your specific business needs. Assess the types of products you aim to print on, as different materials—such as fabrics, plastics, or metals—may demand varying machine capabilities. Additionally, consider the scale of your operations. A small startup may benefit from a simpler, more manual machine, whereas a larger enterprise may require a fully automated system to meet high-volume demands efficiently.

Furthermore, evaluate the level of detail and color complexity needed in your prints. If your designs feature intricate graphics or multiple colors, investing in a machine that offers advanced printing techniques can enhance the quality of your output. It’s also essential to consider the workspace; a compact machine can be beneficial for limited spaces, while larger setups might need dedicated locations. By aligning your machinery choice with these fundamental business requirements, you will ensure that your screen printing investment suits both your current and future operational aspirations.

When selecting a screen printing machine, it's essential to understand the various types available and their specific applications. The most common types include manual, semi-automatic, and automatic screen printing machines. Manual machines are ideal for small businesses or startups that require flexibility and lower initial investment. They allow for hands-on involvement, making them suitable for custom prints and small runs, but they can be labor-intensive and time-consuming.

On the other hand, semi-automatic machines are designed for businesses looking to increase production efficiency without a significant financial commitment. These machines automate some processes, allowing for quicker job changes and reducing the risk of human error. They strike a balance between speed and affordability. For larger operations or businesses focused on high-volume production, fully automatic screen printing machines are the best choice. These machines excel in speed and consistency, handling large runs with minimal operator input, which ultimately maximizes productivity and reduces labor costs. Understanding these types and their applications will help businesses make informed choices to meet their production goals effectively.

| Machine Type | Application | Best For | Price Range |

|---|---|---|---|

| Manual Screen Printing | Small runs, custom jobs | Startups, hobbyists | $300 - $2,000 |

| Automatic Screen Printing | High-volume production | Larger businesses | $20,000 - $200,000 |

| Hybrid Screen Printing | Versatile applications | Medium to large businesses | $10,000 - $100,000 |

| Digital Hybrid Screen Printing | Custom designs, small runs | Graphic designers, print shops | $15,000 - $150,000 |

When choosing the right screen printing machine for your business needs, there are several key features to consider. Firstly, evaluate the print head configuration. Machines can come with a single or multiple print heads, which impacts productivity. A multi-head machine is beneficial for higher volume operations, enabling faster production rates while maintaining print quality.

Moreover, consider the machine's compatibility with various substrates, from textiles to rigid materials, which will expand your printing capabilities.

Another vital aspect is the ease of use and maintenance. Look for machines with user-friendly interfaces and straightforward setup processes. This can save valuable time during production. Regular maintenance is crucial, so opt for models that require minimal upkeep and have readily available replacement parts. Additionally, consider the space where the machine will be used; compact designs are available for smaller operations, whereas larger machines may be necessary for big-scale printing.

Tips: Before making a purchase, test different machines to get a feel for their operation. Pay attention to features such as automatic registration systems, which can significantly reduce setup time and improve alignment accuracy. Moreover, assess the customer support and warranty options offered, as strong support can help you effectively troubleshoot any issues that arise.

When budgeting for your screen printing equipment, the first step is to assess your specific business needs. Consider the type of products you will be printing, the volume of production you expect, and whether you require a manual or automatic machine. Each of these factors can significantly influence the overall cost. A manual machine might be sufficient for smaller operations, while a higher volume production may necessitate the investment in an automatic screen printing machine to maximize efficiency and consistency.

Additionally, it’s essential to account for ancillary equipment and materials, such as screens, inks, and curing units. These items can add up quickly, so it's wise to prioritize your purchases based on immediate needs versus future goals. Creating a comprehensive budget that encompasses both initial setup costs and ongoing operational expenses will help ensure that you're financially prepared for your screen printing venture, while also allowing for flexibility as your business grows.

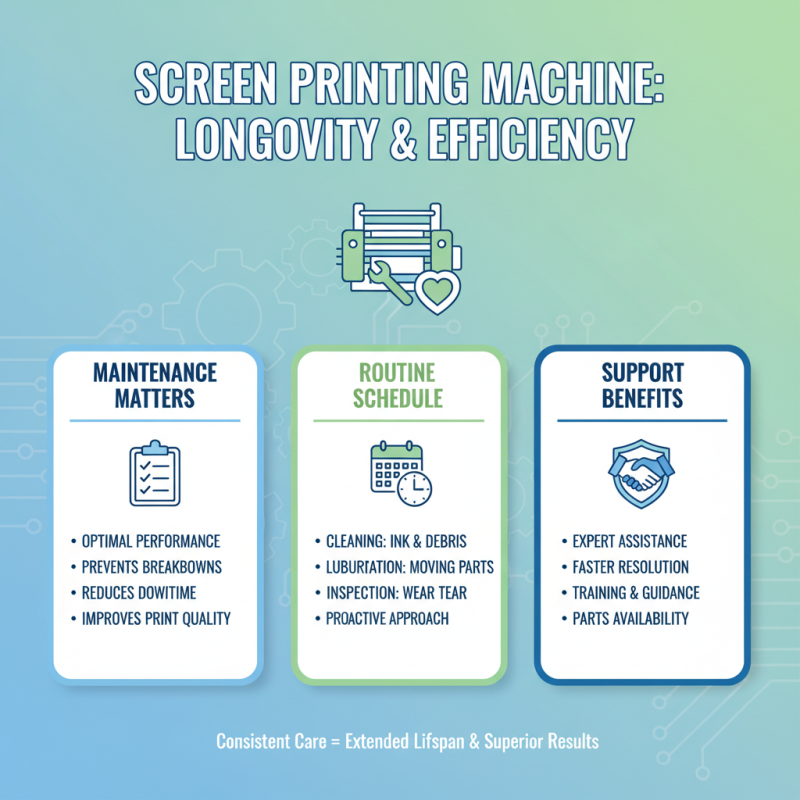

When investing in a screen printing machine, maintenance and support are critical factors that can significantly affect the longevity and efficiency of your equipment. Regular maintenance helps to ensure that the machine operates at optimal levels, preventing costly breakdowns and reducing downtime. It is essential to establish a consistent maintenance schedule that includes cleaning, lubrication, and inspection of moving parts. This proactive approach not only prolongs the lifespan of the machine but also enhances print quality, ensuring that your business produces consistent and professional results.

Moreover, having access to robust customer support is invaluable when navigating the complexities of screen printing machinery. A dependable support system can provide troubleshooting assistance, spare parts, and technical guidance when unexpected issues arise. It is beneficial to choose a supplier or manufacturer that offers comprehensive support services, including online resources, user manuals, and responsive customer service teams. By prioritizing maintenance and support, businesses can create a reliable operation, enhance productivity, and focus on delivering high-quality prints to their customers.