Choosing the right Oval Printing Machine can significantly impact your business success. The global printing market is expected to reach $496 billion by 2026, driven by advancements in technology and increasing demand. With the right machinery, companies can enhance their branding and product presentation.

Industry expert, John Smith, states, "Investing in a quality Oval Printing Machine is essential for meeting modern consumers' expectations." His insights underscore the importance of selecting machines that ensure high-quality output and efficiency. Many businesses fail to realize that not all machines deliver equal results.

When selecting an Oval Printing Machine, consider factors such as production speed, print quality, and material compatibility. It's easy to get overwhelmed by choices. However, neglecting these details can lead to potential setbacks. In some cases, businesses find themselves unhappy with their machine choice after purchase. Being informed and reflective on your options is key to making the best decision.

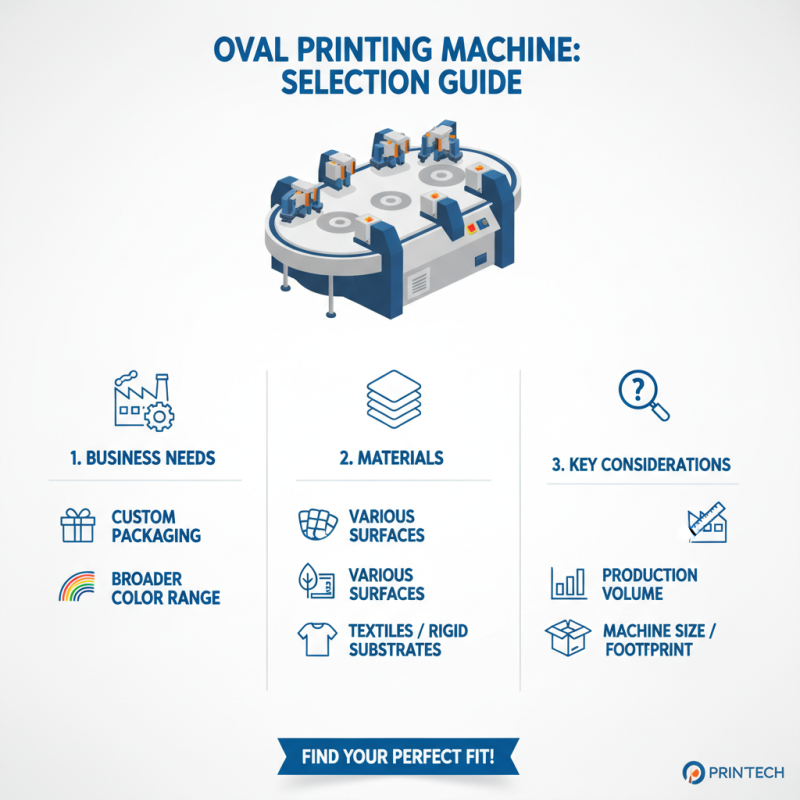

When selecting an oval printing machine, understanding your business needs is crucial. Different industries require specific features. For instance, if your business focuses on custom packaging, a machine with a broader color range might be essential. Consider the materials you will print on. Some machines handle various surfaces better than others. Finding the right fit can be challenging.

Reflecting on your production volume is also important. A machine designed for high output may not be necessary for small projects. On the other hand, underestimating your needs could lead to bottlenecks. Think about the level of detail required in your prints. Some machines excel in precision, while others might not deliver the same quality.

Lastly, invest time in understanding maintenance and support. Machines can break down unexpectedly. Having local support can save you significant downtime. However, not all models offer robust customer service. By analyzing these factors, you can make a more informed decision.

When selecting an oval printing machine, key features can make a significant impact. Consider the print size and material compatibility. Machines vary in their ability to handle different substrates. Ensure your choice supports the materials you plan to use, from plastics to textiles. This compatibility is crucial for achieving consistent results.

Tips: Look for a machine that offers adjustable print settings. This feature allows for flexibility based on your projects. It can accommodate different designs and sizes, optimizing your output.

Print speed is also essential. Faster machines can boost your production levels. However, always weigh speed against quality. Sometimes, a slower machine produces superior prints, making it more valuable in the long run. Reflect on your business needs.

Finally, user-friendliness matters. A complicated interface can lead to mistakes and delays. Choose machines that offer intuitive controls. Test the ease of setup and operation as part of your evaluation.

When considering oval printing machines for your business, it's crucial to compare the various types available. Some machines are designed for high volume, while others are tailored for specialized jobs. For example, digital oval printing machines are great for short runs. They offer flexibility in design and quick turnaround times. However, they may not be suitable for larger batches.

Tips: Look for a machine that allows for easy adjustments. You might need to switch between different sizes and materials. An adaptable machine could save time and costs down the line.

On the other hand, traditional screen printing machines can produce vibrant colors and are ideal for large orders. However, the setup time can be lengthy, which may not be efficient for all businesses. Consider your production schedule carefully.

Tips: Think about your operational needs. If speed is essential, digital options might be worth exploring. But if quality is your priority, traditional methods could shine. Examine these factors and weigh your options accordingly.

When choosing an oval printing machine, budget plays a crucial role. Many businesses face a challenge: balancing cost with quality. High-end machines offer exceptional print quality but require a significant investment. On the other hand, more affordable options can compromise on features. You may find that cheaper machines often lack durability. This can lead to higher maintenance costs down the line.

Consider your production needs carefully. A low-quality machine might save money initially, but it may result in subpar prints. This could impact your brand’s reputation. Examine the materials and colors you plan to print. Some machines excel in specific applications while struggling in others. Investing in a versatile machine can pay off in the long run. Analyze your budget but also think about potential growth. Sometimes, it’s wiser to spend more now for reliable, long-lasting equipment.

Don't forget to factor in ongoing costs. Things like ink and maintenance can add up quickly. Make a list of features that are essential for your work. This ensures that you don’t overspend on unnecessary upgrades. Be wary of features that sound appealing but don't serve your primary printing needs. The right balance between cost and quality requires careful thought. Reflection on your specific needs is key to making the best choice.

When investing in an oval printing machine, maintenance is crucial for longevity. Regular upkeep prevents minor issues from becoming major problems. Clean the machine frequently to avoid ink buildup. Dust can lead to operational issues, affecting print quality. Check for wear and tear on parts regularly.

Tips for maintenance:

1. Schedule weekly deep cleaning sessions.

2. Use manufacturer-recommended cleaning solutions.

3. Keep the machine sheltered from dust.

Proper support from your supplier is equally important. Ensure they provide reliable customer service. Ask about their response time. A quick repair service can minimize downtime. Evaluate their warranty options carefully. You want a plan that covers essential parts.

Don’t overlook operator training. Untrained staff can make mistakes that lead to damage. Invest time in training sessions to improve skills. This will pay off in reduced maintenance needs and better prints. Reflect on your current processes. Is your team well-prepared? Identifying gaps can lead to improvements.