In today's competitive market, choosing the right equipment can make or break a business. A Screen Printing Machine offers unparalleled versatility and efficiency for custom designs. With a screen printing machine, businesses can create vibrant prints on various materials, from fabrics to promotional items. This versatility allows for creativity and uniqueness in branding.

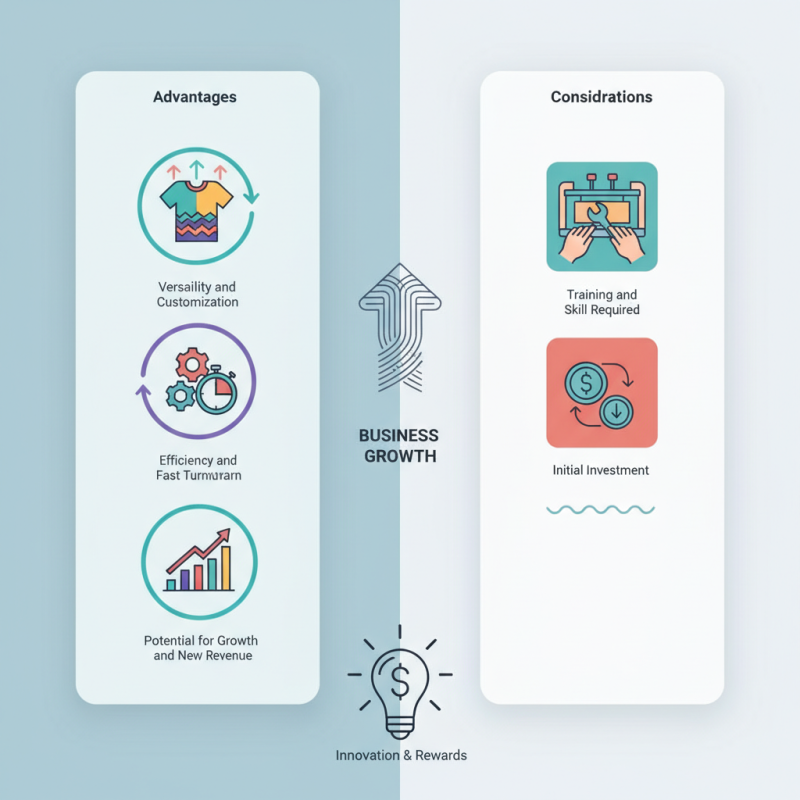

Investing in a screen printing machine can be daunting. However, the advantages often outweigh the initial costs. It enables high-quality production and fast turnaround times. Customization is key in attracting customers, and screen printing delivers vibrant results that stand out. Yet, there are challenges. Operating such machinery requires training and skill. It may take time to master the process and achieve desired outcomes.

Consider the potential for growth. A screen printing machine not only fulfills current demand but also opens new revenue streams. Businesses can expand their product offerings and appeal to broader markets. This investment may seem large, but with careful planning, it is achievable. The potential rewards for creativity and innovation in your business are immense.

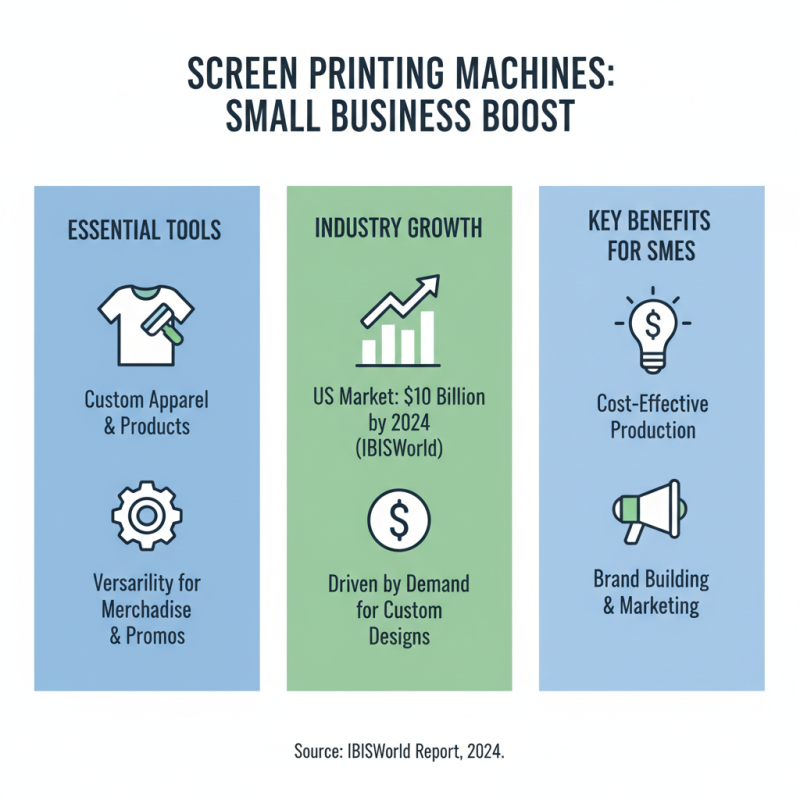

Screen printing machines have become essential tools for small businesses looking to create custom apparel and products. According to a recent IBISWorld report, the screen printing industry in the U.S. is expected to generate over $10 billion in revenue by 2024. This growth highlights the demand for custom designs, particularly in clothing, promotional materials, and merchandise.

One major advantage of using a screen printing machine is cost efficiency. Businesses can produce large quantities of items quickly. A screen printing press can churn out hundreds of shirts per hour. This efficiency often leads to higher profit margins. However, it requires an initial investment and training to master the equipment. Small business owners should be aware of the learning curve involved.

Versatility is another benefit. Screen printing supports various materials, from textiles to ceramics. This capability opens doors for unique products. Yet, some might find that not every design works well with screen printing. Intricate details and color gradients may not translate perfectly. Being mindful of these limitations is crucial for achieving high-quality prints. The potential for creativity and profit is significant, but reflection on techniques is often necessary.

When deciding on a screen printing machine for your business, it's vital to consider key features that can enhance your productivity. A reliable machine should offer consistent print quality. Research indicates that over 70% of printing businesses prioritize quality as a top feature. Ensure the machine supports various materials like cotton, polyester, and blends. This versatility is crucial for meeting diverse customer demands.

The speed of the machine also plays a pivotal role. Studies show that faster machines can produce up to 50% more prints per hour compared to standard models. This efficiency can significantly impact your bottom line. Look for machines with adjustable speeds and quick setup times. These elements can streamline your workflow and reduce downtime.

Tips: Before purchasing, test different machines if possible. Assess their setup complexity. A machine that seems perfect might have a steep learning curve. Additionally, consider maintenance ease. Some machines require extensive upkeep, which can eat away at your profits. Make a checklist of what features matter most to you. Reflect on past experiences with printing equipment to guide better decision-making.

| Feature | Description | Importance |

|---|---|---|

| Print Size | Maximum area the machine can print on a substrate. | Essential for determining the type of projects. |

| Print Speed | How fast the machine can print designs. | Affects overall productivity and turnaround time. |

| Ease of Use | How user-friendly the machine is for operators. | Reduces training time and errors. |

| Durability | Longevity and robustness of the machine. | Ensures a good return on investment. |

| Versatility | Ability to print on various materials. | Important for expanding service offerings. |

| Maintenance Requirements | Frequency and type of maintenance needed. | Affects operational downtime and costs. |

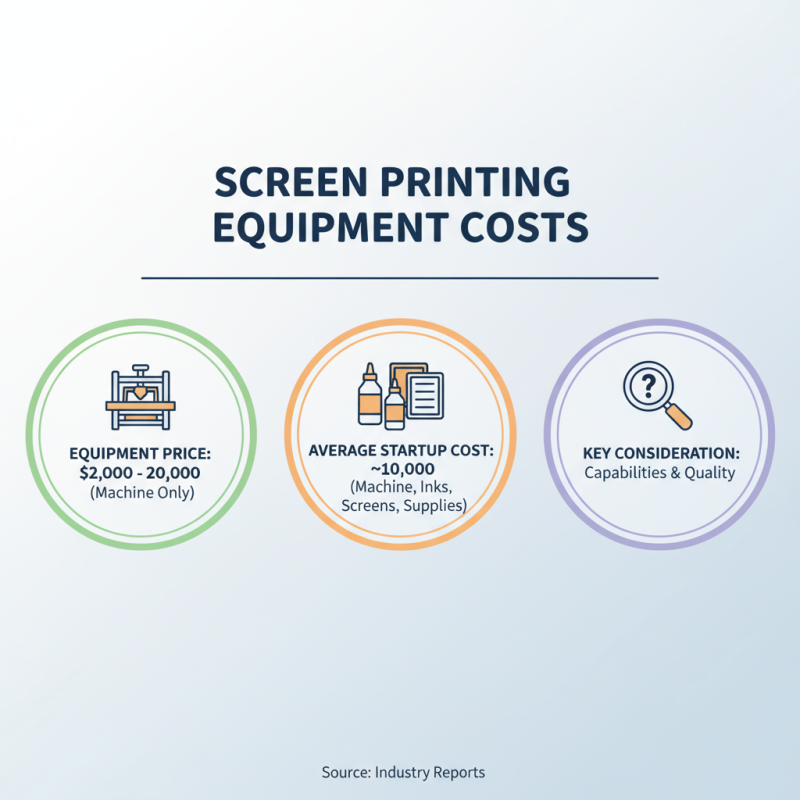

Investing in screen printing equipment involves careful consideration of costs. A high-quality screen printing machine can range from $2,000 to $20,000, depending on its capabilities. According to industry reports, the average cost of setting up a small to medium screen printing operation can be around $10,000. This includes not only the machine but also inks, screens, and other essential supplies.

Understanding ongoing expenses is crucial. Ink costs can fluctuate significantly. A gallon of quality ink may cost between $30 and $60, and you will need multiple colors for varied designs. Screens and stencils wear out, leading to additional costs every few months. Estimates suggest that maintenance can add 15% to your yearly expenses.

Considering the return on investment is also essential. A well-operated screen printing business can generate profits of 30% to 50% per job. However, the initial setup may seem daunting. Many new businesses underestimate the cost of materials and labor. They often overestimate their hourly output, leading to pressure on margins. It's vital to evaluate both potential earnings and actual expenditures to achieve long-term success.

Screen printing stands out among various printing techniques. It offers durability. This method uses layers of ink pressed through screens. The result is vibrant, long-lasting prints. According to industry reports, screen printing accounts for approximately 40% of textile printing. This statistic highlights its popularity in fashion and merchandising.

In contrast, digital printing is often faster. However, it may not match the vibrancy of colors achieved through screen printing. Digital processes can be costly, especially for large runs. The upfront investment in a screen printing machine pays off over time. Production costs decrease as volume increases.

Tips: Consider your target market. If you focus on custom apparel, screen printing offers personalized results. Test different inks to evaluate their durability and colorfastness. Always factor in production time. Planning can help avoid bottlenecks. Balancing print quality and efficiency is key. Reflect on your business needs. Choose a method that aligns with your brand’s goals.

Maintaining a screen printing machine is crucial for its longevity. Regular cleaning is essential. Dust and ink residue can build up and affect performance. Use a soft cloth to wipe down surfaces daily. Check for any damage after each use. Small issues can turn into big problems if ignored.

Calibration should be done regularly. Misaligned screens lead to uneven prints. Even slight misalignment can ruin a batch of products. Take time to adjust and test before large runs. It might seem tedious, but it pays off. Proper tensioning of screens is another key area. Too tight or too loose can cause issues. Find that sweet spot to ensure quality prints.

Don't forget about ink storage. Improper storage can lead to drying out and clumping. Keep inks sealed and cool. Check expiration dates. If ink looks off, discard it. Always test before starting a job. Machine upkeep may feel repetitive. Yet, each step is essential for reliable performance. Neglect leads to costly downtime.