In the ever-evolving world of fashion and merchandise, the significance of a Clothing Printing Machine cannot be overstated. Renowned industry expert, John Taylor, emphasizes, “Investing in a clothing printing machine pays off quickly.” With businesses moving towards customization, this machine holds immense potential.

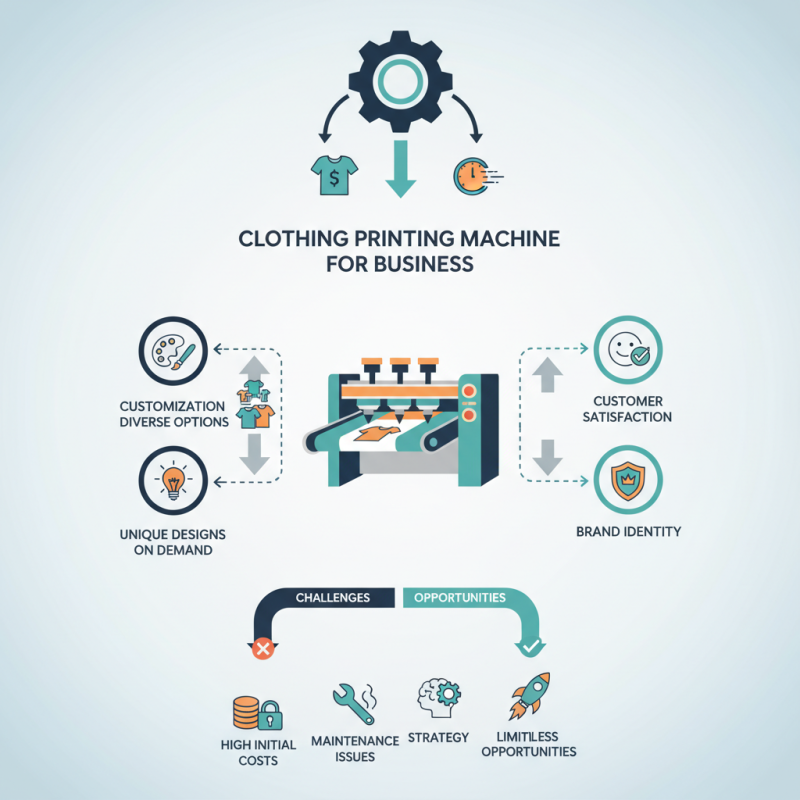

Entrepreneurs now seek diverse printing options. The market demands personalized apparel. A Clothing Printing Machine allows for creativity and speed. Imagine producing unique designs on demand, reducing excess inventory. This approach not only satisfies customer wishes but also enhances brand identity.

Yet, it's not without challenges. High initial costs and maintenance issues can deter some businesses. Understanding how to effectively leverage this technology is crucial. A well-planned strategy can unveil limitless opportunities. Hence, reflecting on the integration of a Clothing Printing Machine in your operations is key to thriving in this competitive market.

Investing in a clothing printing machine can transform your business. It allows for customization, enabling unique designs for clients. Customization is crucial in today's market. Customers seek personalized products. They want items that reflect their individuality.

A printing machine can enhance production efficiency. You can create multiple pieces in a short time. This process reduces labor costs and speeds up delivery. However, it's important to consider maintenance. Regular upkeep is necessary to avoid breakdowns. Skipping maintenance may lead to costly repairs.

Moreover, having your printing setup can improve quality control. You can oversee the entire process. This control means fewer errors and higher customer satisfaction. Yet, with such power comes responsibility. Businesses must ensure ethical practices in sourcing materials. Balancing creativity and responsibility is essential for lasting success.

When considering a clothing printing machine for your business, various types are available. Each type serves different printing needs.

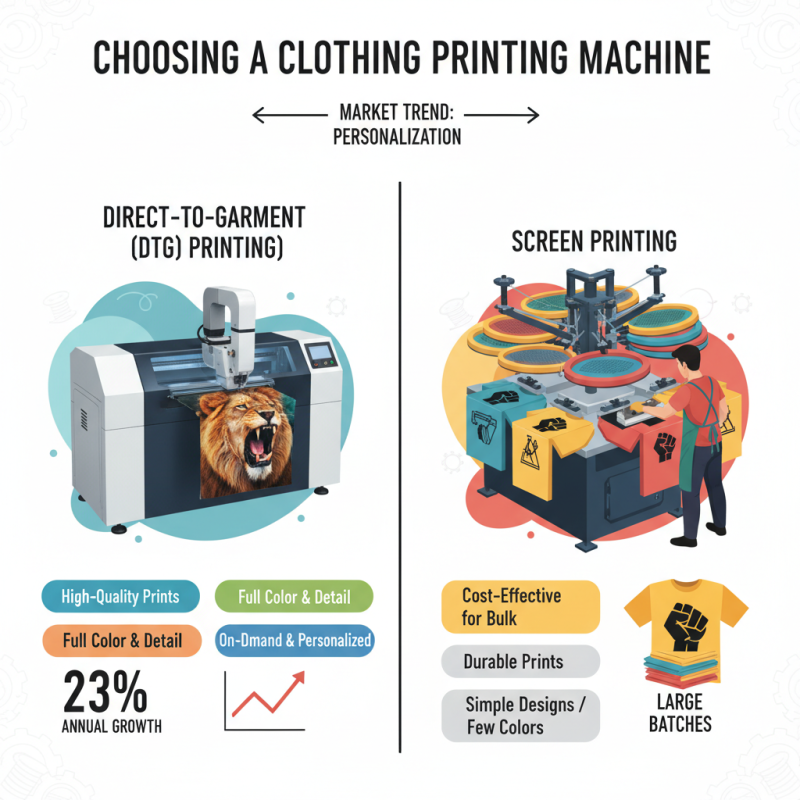

Direct-to-Garment (DTG) printers offer high-quality prints with fine details. They work well for custom designs and small runs. This versatility can be great for brands focused on unique items.

Another popular option is screen printing. It is ideal for bulk orders, providing vibrant colors and durability. However, setup costs can be higher. If you need fast production for larger quantities, screen printing might be the way to go. Keep in mind that each method has its pros and cons.

Tip: Assess your target market. Knowing what styles and quantities you need will help guide your choice.

Sublimation printing is another process worth mentioning. It works best with polyester fabrics, allowing for full-color images with stunning results. However, limitations on fabric types mean careful selection is needed. This could result in missed opportunities if not properly addressed.

Tip: Research your fabric options. Different machines work better with specific materials. Understanding this will optimize your printing capabilities.

When choosing a clothing printing machine, several key factors should be considered. The type of printing technology is crucial. Direct-to-garment (DTG) printers provide high-quality prints with vibrant colors. Meanwhile, screen printing machines are cost-effective for larger batches. According to industry reports, DTG will grow at a rate of 23% annually. It captures the increasing demand for personalized apparel.

Speed and efficiency also matter. Machines vary in their throughput capabilities. Some can print up to 100 shirts per hour, while others may handle fewer. A slow machine may frustrate your workflow. It can hinder your ability to meet customer demands. Additionally, consider the cost of maintenance. Frequent service can eat into your profits. Some advanced machines come with intricate technology but may require dedicated technicians.

Another important aspect is the size and space required. Not all businesses have room for bulk machinery. Compact models may offer flexibility for smaller shops. However, they often lack features found in larger equipment. This trade-off may affect your production quality. Ultimately, your choice should align with your business goals and customer needs. Balancing quality and cost is essential for success in a competitive market.

Investing in a clothing printing machine can seem daunting. The initial cost may appear high, but consider long-term benefits. Traditional printing methods can be expensive. They involve materials and labor costs that add up quickly. A printing machine allows for on-demand production, reducing waste and excess stock.

Think about maintenance costs too. Machines require upkeep to function properly. Neglecting maintenance could lead to larger repair expenses later. Evaluate the potential return on investment from fewer errors and quicker turnaround times. This is where the true value shines through.

**Tips:** Start small. Analyze your business scale. A compact machine may suffice in the beginning. Research potential buyers for custom prints, enhancing customer engagement. Always compare operating costs before deciding. Understand your market's needs. A well-placed investment can lead to substantial growth, but it requires careful planning and evaluation.

When investing in a clothing printing machine, maintenance is often overlooked. Regular upkeep is crucial for optimal performance. Dust and fabric remnants can accumulate quickly, leading to print quality issues. Ignoring these details can result in frustration and wasted materials.

Support is just as important as maintenance. A responsive support team can address issues that arise unexpectedly. Whether it's a software glitch or mechanical failure, timely assistance can minimize downtime. However, not all support services are equal. Some might leave you hanging during critical moments.

Being proactive about both maintenance and support can safeguard your investment. Routine checks can help identify potential problems early. Communication with support teams should be straightforward. Yet, sometimes, responses may not meet expectations, leading to additional challenges. It's essential to assess both aspects as you enhance your printing capabilities.

| Feature | Description | Maintenance Frequency | Support Availability |

|---|---|---|---|

| Printing Speed | High-speed printing capable of producing large volumes in a short time. | Daily checks | 24/7 customer service |

| Print Quality | Full-color high-resolution prints with vibrant colors. | Weekly calibration | Email and chat support |

| Ease of Use | User-friendly interface designed for easy operation. | Monthly maintenance checks | On-site technical support available |

| Cost Efficiency | Reduces printing costs and increases profit margins. | Quarterly service inspection | Training and workshops provided |