In today's competitive fashion landscape, businesses often look for efficient solutions. Investing in a Clothing Printing Machine can set your brand apart. Industry expert John Smith once said, "The right printing machine transforms creativity into revenue." This underscores the potential impact on profits and customer satisfaction.

Clothing printing technology is advancing rapidly. A quality printing machine elevates product offerings and streamlines operations. It allows for customization and quicker turnaround times, meeting market demands. However, the initial cost can be daunting. Small businesses might hesitate, fearing they won't recoup the investment.

Nevertheless, a Clothing Printing Machine serves as a cornerstone for growth. It empowers brands to offer unique designs that resonate with customers. Despite the challenges, the long-term benefits often outweigh the risks. It's essential to weigh options carefully, ensuring that the machine aligns with your business vision.

Investing in a clothing printing machine can greatly enhance your business's profitability. According to a recent report by Smithers Pira, the global digital textile printing market is expected to reach $4.9 billion by 2024, growing at a rate of 12% annually. With such growth, businesses that incorporate printing technology can tap into a lucrative market. The ability to produce custom apparel on demand can significantly reduce inventory costs and waste.

Customization is a key benefit of using a clothing printing machine. Customers increasingly seek personalized products. A study from Grand View Research highlighted that 70% of consumers are willing to pay extra for customized items. This trend signifies that businesses can attract more customers by offering unique designs. Additionally, high-quality printing techniques ensure vibrant and long-lasting designs, enhancing overall customer satisfaction.

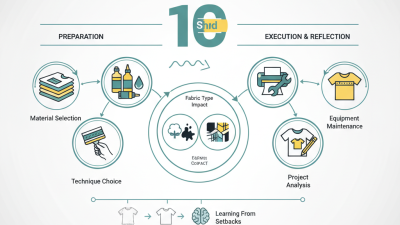

Tip: Emphasize the need for experimentation. The first few designs may not hit the mark. Continuous feedback and adjustment are crucial for success.

Another noteworthy point is the reduction in turnaround times. Traditional printing often takes days or weeks. In contrast, digital printing can produce items in hours. This efficiency allows businesses to respond quickly to trends and customer demands. However, it's important to reflect on maintaining quality. Fast production may sometimes compromise the final product. Balancing speed with quality assurance is essential.

Tip: Invest time in training your staff on the printing machine's capabilities. Well-trained personnel can prevent costly errors and improve output quality.

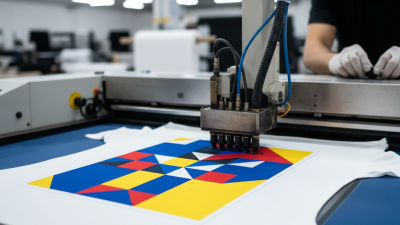

Choosing the right clothing printing machine can transform your business. There are several types of machines, each with specific functions. Direct-to-Garment (DTG) printers are popular for detailed designs. They work well for small batches and varied colors. However, they may struggle with large orders and heavy fabrics.

Screen printing machines offer durability and speed. They excel in producing vibrant colors for bulk items. Yet, the setup can be time-consuming and requires more space. Sublimation printers are another option for polyester fabrics. They create stunning images with a smooth finish. Unfortunately, they can't work on cotton materials.

Laser printers are great for simpler designs and small runs. They're easy to operate and maintain. But, the detail may not match that of DTG printers. Consider your specific needs carefully. The right machine can make a significant difference in your operations.

In recent years, many businesses have shifted towards in-house clothing printing. This decision often hinges on cost-effectiveness. According to industry reports, in-house printing can reduce costs by up to 30% compared to traditional outsourcing. When businesses print their own clothing, they eliminate markup fees imposed by third-party printing services.

Owning a clothing printing machine also enables faster turnaround times. Businesses can respond to customer orders promptly. This can lead to increased sales and higher customer satisfaction. A survey found that 57% of consumers prefer brands with faster delivery options. However, not all businesses are equipped to handle in-house printing efficiently. The initial investment in machinery can be significant, sometimes exceeding $10,000. This is a challenge for smaller businesses.

Moreover, maintenance and training costs are often overlooked. Machines can malfunction. Employees need training to operate them correctly. Without proper oversight, the benefits of in-house printing can diminish. Businesses must balance these costs with the potential savings from not outsourcing. In-house printing is not a one-size-fits-all solution. Each business should carefully evaluate its needs before committing.

Clothing printing machines offer diverse applications across various industries. In fashion, they enable designers to create custom patterns and graphics. This flexibility allows for unique pieces that stand out in a crowded market. Small businesses often use these machines for one-off designs, catering to niche markets.

In the promotional industry, clothing printing machines are invaluable. Companies can easily print logos on shirts or caps for events. Custom merchandise can drive brand recognition. However, sometimes the quality does not meet expectations. Testing samples before a large run is essential.

Tips: Always evaluate the machine's printing speed and capacity. This helps meet demand without delays. Also, consider the types of inks used. Some inks provide more vibrant and durable results. Experimenting with different materials can lead to unexpected, yet appealing outcomes.

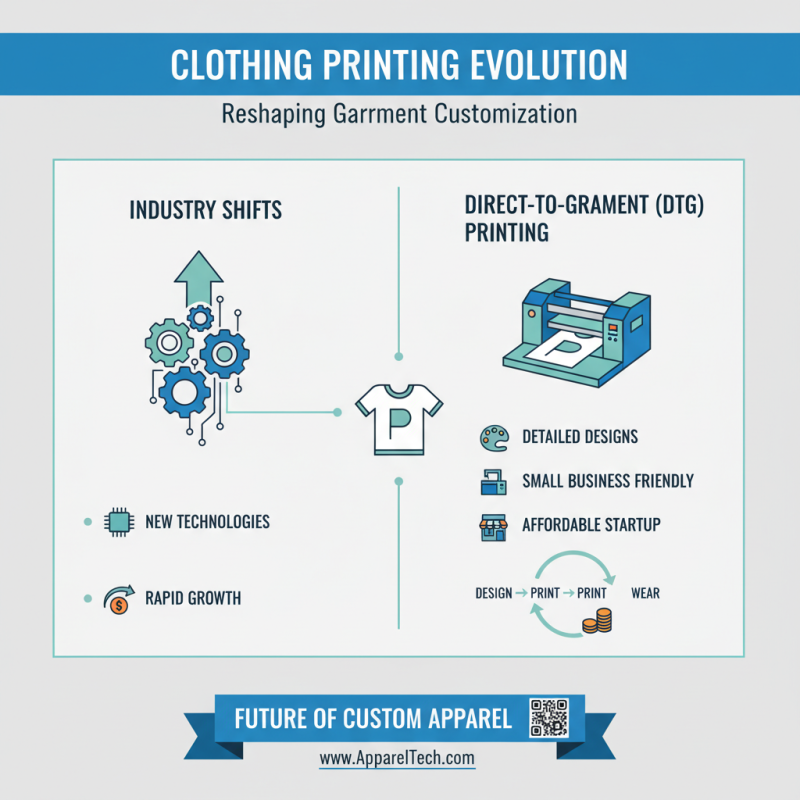

The clothing printing industry is evolving rapidly. New technologies are reshaping how businesses approach garment customization. One notable trend is direct-to-garment (DTG) printing. This method allows for detailed designs on fabric. It opens doors for small businesses with limited budgets.

Innovations like eco-friendly inks are gaining traction. These inks produce vibrant colors without harming the environment. This choice appeals to eco-conscious consumers. Additionally, advancements in printing speed improve productivity. Businesses can now meet growing demands without sacrificing quality. However, investing in these technologies often comes with challenges.

Many companies struggle to keep up with maintenance and training. Integrating new equipment requires commitment and time. Moreover, the rapid pace of change means that some technologies may quickly become obsolete. Business owners must stay informed and be adaptable.