When it comes to enhancing your business's production capabilities, selecting the right equipment is crucial. One key piece of machinery that many businesses are considering is the Sleeve Printing Machine. This versatile device allows for efficient printing on a variety of items, making it a popular choice for companies focused on customization and branding. However, with a plethora of options available on the market, choosing the best Sleeve Printing Machine for your specific business needs can be daunting.

Understanding your unique requirements is the first step in making an informed decision. Whether you are printing on bottles, containers, or other cylindrical objects, different machines offer various features and capabilities that can directly impact the quality of your output and the efficiency of your production process. In this guide, we will explore the essential factors to consider when selecting a Sleeve Printing Machine, enabling you to invest wisely and enhance your operational efficiency. By the end, you'll be better equipped to make a choice that aligns perfectly with your business goals.

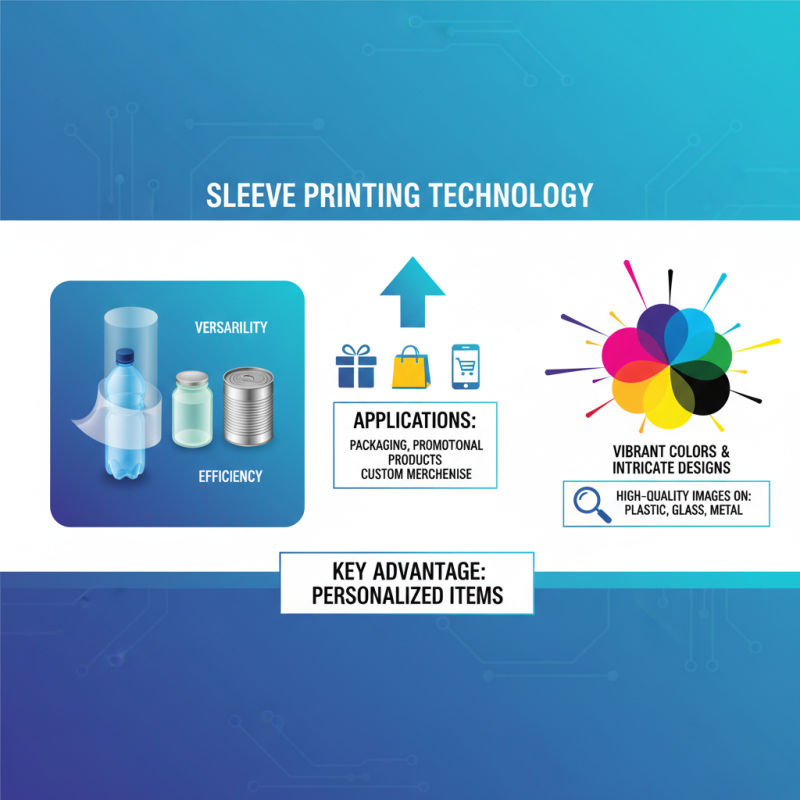

Sleeve printing technology has gained prominence due to its versatility and efficiency in various applications. This method utilizes a cylindrical sleeve, typically made from flexible material, that wraps around the substrate to facilitate the printing process. The primary advantage of sleeve printing lies in its ability to produce high-quality images on a range of surfaces, including plastic, glass, and metal, making it ideal for packaging, promotional products, and custom merchandise. Its capacity for vibrant colors and intricate designs caters to the growing demand for personalized items in the market.

Understanding the applications of sleeve printing technology is crucial for businesses looking to enhance their product offerings. Industries such as food and beverage, cosmetics, and pharmaceuticals significantly benefit from this printing method, as it allows for eye-catching labels that improve product visibility on retail shelves. Additionally, sleeve printing supports short production runs, which is essential for companies intending to test new designs or respond quickly to market trends. As businesses continue to seek innovative ways to attract customers, mastering sleeve printing technology can be a pivotal step in achieving competitive advantage.

When selecting a sleeve printing machine for your business, it's crucial to consider several key features that can greatly impact your production efficiency and quality. First and foremost, pay attention to the machine’s printing speed and its capability to handle varying sleeve sizes. A machine that can adapt to different dimensions allows for versatility in your product offerings, ensuring you can cater to diverse customer needs without downtime for adjustments.

Another vital aspect is the technology employed in the printing process. Look for machines that utilize advanced printing technologies such as digital or flexographic printing. These methods not only enhance the quality of the prints but also offer quicker turnaround times. Additionally, consider the ease of use and maintenance of the machine. A user-friendly interface and readily available support can significantly reduce training times and operational challenges.

Tips for choosing the right machine include evaluating your production volume and long-term business goals. If you anticipate growth, investing in a machine that scales with your business is a smart decision. Also, engage with other businesses or professionals in the industry to gather insights and recommendations. By thoroughly assessing these features and gathering relevant information, you can make an informed decision that aligns with your business needs.

When selecting a sleeve printing machine, evaluating production capacity and speed is paramount to align with your business's operational needs. According to a recent report by Smithers Pira, the global market for sleeve printing is projected to grow at a CAGR of 4.2% from 2021 to 2026, reflecting a rising demand for efficient packaging solutions. This growth emphasizes the importance of investing in a machine that not only meets current production demands but also has the potential to adapt to future growth.

Speed is an essential factor for maximizing productivity. Machines that operate at speeds exceeding 500 units per minute provide significant advantages for businesses looking to scale operations. Recent industry insights reveal that companies utilizing high-speed machines can achieve production rates that are 30% more efficient, allowing for quicker turnaround times and reduced labor costs. Therefore, when evaluating your options, it’s crucial to consider your expected output volumes and how the machine’s specifications align with those targets.

In addition to speed, assessing the production capacity is vital to ensure that the chosen machine can handle peak production times without compromising quality. Reports indicate that businesses that strategically invest in machines capable of scalable production often report a 15-20% increase in overall operational efficiency. This statistical advantage further highlights the necessity for thoughtful consideration of both the speed and capacity of sleeve printing machines to facilitate growth and maintain competitive edges in the market.

| Machine Model | Production Capacity (Units/hour) | Max Print Speed (m/min) | Print Resolution (dpi) | Setup Time (min) | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 800 | 50 | 1200 | 15 | 15,000 - 20,000 |

| Model B | 500 | 45 | 1500 | 20 | 10,000 - 15,000 |

| Model C | 1000 | 60 | 1200 | 10 | 18,000 - 25,000 |

| Model D | 600 | 55 | 1800 | 25 | 12,000 - 16,000 |

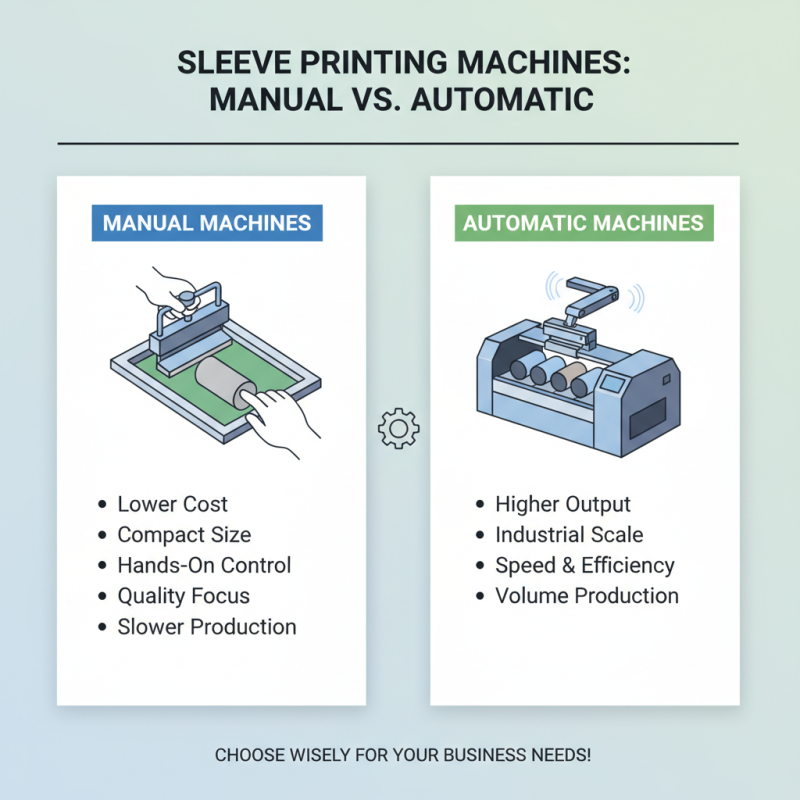

When it comes to selecting the right sleeve printing machine for your business, understanding the various types can significantly influence your decision. Sleeve printing machines generally fall into two major categories: manual and automatic. Manual machines are often more cost-effective and require less floor space, making them ideal for small businesses or startups. They allow for more hands-on control of the printing process, which can be a significant advantage for those who prioritize maintaining quality and detail in their work. However, the production speed and efficiency tend to be lower compared to their automatic counterparts.

On the other hand, automatic sleeve printing machines are designed for higher volume production, providing rapid printing capabilities that cater to larger businesses. These machines often come equipped with advanced features such as digital controls and the ability to handle a wide variety of sleeve sizes and materials. While the initial investment might be steeper, the long-term benefits in terms of productivity and reduced labor costs can outweigh the upfront expense. In addition, automatic machines typically ensure consistent quality, which is critical for maintaining brand standards across larger batches of printed materials. Understanding the specific requirements of your business, including production volume and desired print quality, will aid you in making an informed choice between these types of sleeve printing machines.

When considering the purchase of a sleeve printing machine, budgeting is a crucial aspect that can significantly impact your business's bottom line. According to a recent industry report from Smithers Pira, the digital printing market is expected to reach $29.4 billion by 2027, largely driven by the demand for customized packaging solutions. Investing in a sleeve printing machine can help businesses capitalize on this trend, but understanding the cost implications is essential.

Typically, the initial investment for a high-quality sleeve printing machine can range from $30,000 to $250,000, depending on the machine's specifications, capabilities, and features. Additionally, ongoing costs such as maintenance, ink, and substrate materials should not be overlooked. A study by InfoTrends indicates that operational costs can account for up to 30% of a business's total printing expenditure. Therefore, establishing a realistic budget that encapsulates both upfront and operational costs will ensure that your investment aligns with your financial goals and growth expectations.

Moreover, it’s essential to assess the return on investment (ROI) associated with these machines. The same InfoTrends study showed that companies investing in advanced printing technologies experienced an ROI ranging from 20% to 50% over three years. By strategically incorporating sleeve printing machines into your production line, you can not only enhance efficiency and output quality but also improve your overall profitability in today's competitive market.