In the ever-evolving landscape of printing technology, selecting the right Silk Screen Printer has become crucial for businesses aiming to elevate their branding and product quality. According to a recent industry report by Smithers Pira, the global silk screen printing market was valued at approximately $4.1 billion in 2021 and is projected to witness a compound annual growth rate (CAGR) of 3.5% through 2026. This growth is driven by the increasing demand for custom printing solutions across various sectors, including textiles, packaging, and promotional products.

Expert insights highlight the importance of making informed choices when navigating this specialized field. James Thompson, a renowned industry consultant and author of "The Future of Textile Printing," emphasizes, “The effectiveness of a Silk Screen Printer is not just about the machinery; it’s about understanding the unique needs of your project and aligning them with the capabilities of the printer.” With a plethora of options available, businesses must consider factors such as the printer's technical specifications, printing material compatibility, and overall production capacity to ensure they meet their specific needs. By taking these elements into account, companies can position themselves for success in delivering high-quality prints that resonate with their target audiences.

Understanding your printing requirements is essential when selecting the best silk screen printer for your projects. Start by assessing the type of material you plan to print on, as different printers are designed for various substrates, including fabric, plastics, or paper. Consider the colors and complexity of your designs, as some printers may have limitations in terms of color fidelity and the ability to reproduce intricate details. This evaluation will help you narrow down potential printers that can meet your specific needs.

Additionally, think about the volume of printing you anticipate. If you require high-volume production, investing in a heavy-duty printer that can handle large runs efficiently will save you time and costs in the long run. On the other hand, if you are working on occasional projects or small orders, a more compact and versatile printer may suffice. Understanding these requirements not only streamlines the selection process but also ensures that the machine you choose aligns perfectly with your artistic vision and practical needs.

| Feature | Description | Considerations |

|---|---|---|

| Printing Speed | The number of units printed per hour. | Essential for meeting tight deadlines. |

| Print Quality | Resolution and vibrancy of the printed designs. | Necessary for high-end graphics. |

| Material Compatibility | Types of materials that can be printed on. | Check compatibility with your product materials. |

| Cost | Price per unit and minimum order quantities. | Evaluate against your budget and needs. |

| Turnaround Time | Time taken from order to delivery. | Match with your project timelines. |

| Customer Service | Support and assistance throughout the printing process. | Important for communication and problem resolution. |

| Environmentally Friendly Options | Use of sustainable materials and processes. | Consider if sustainability is a priority for your brand. |

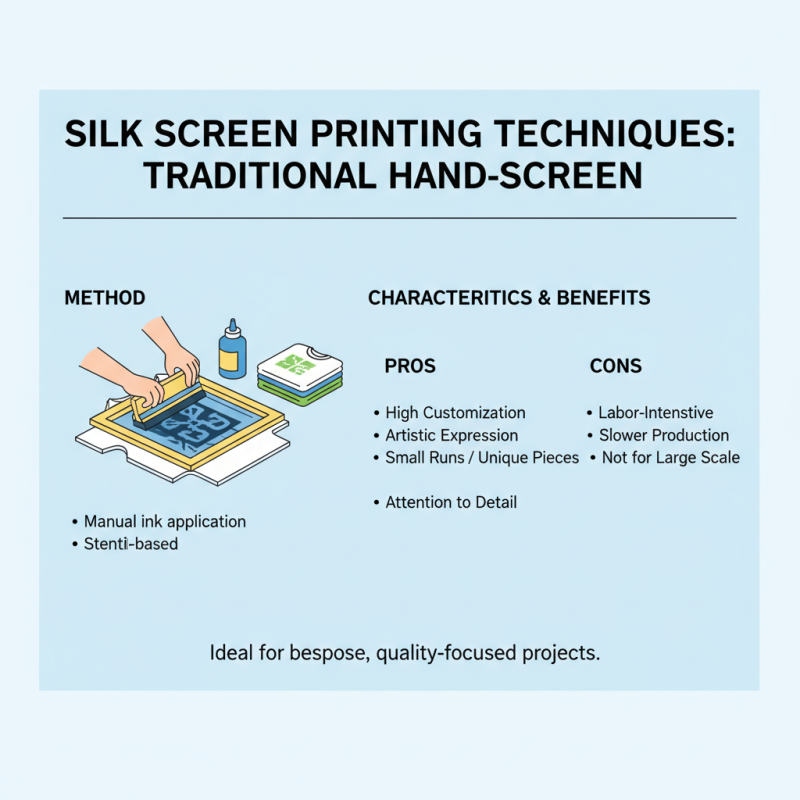

When evaluating different silk screen printing techniques, it’s important to understand the unique characteristics and benefits of each method. Traditional hand-screen printing involves manually pushing ink through a stencil, allowing for a high level of customization and artistic expression. This technique is particularly advantageous for small runs or one-of-a-kind pieces, where the attention to detail can set your work apart. However, it can be labor-intensive and slower than other methods, which may not be ideal for larger production needs.

On the other hand, automated screen printing machines have revolutionized the industry by enhancing efficiency and consistency. These machines can produce large volumes of prints quickly, making them suitable for bulk orders. Additionally, they reduce human error, ensuring that each print maintains the same quality and precision. The choice between manual and automated techniques often comes down to the scale of production required and the desired level of detail in the final product. Understanding these nuances can help you select the right approach to meet your specific printing needs effectively.

Choosing the right silk screen printer can significantly influence the quality and efficiency of your printing projects. When assessing options, it’s essential to identify key features that cater to your specific needs. Firstly, consider the type of printer; automatic or semi-automatic machines can boost productivity, particularly for high-volume jobs. According to a recent industry report, automated printers can increase output by up to 300% compared to manual alternatives.

Another critical feature is the print resolution. High-quality printers typically offer resolutions exceeding 1200 DPI, which is vital for detailed designs and vivid colors. Furthermore, investigate the range of materials the printer can handle. Many high-performing models are capable of printing on diverse substrates including textiles, plastics, and metals, allowing for flexible project capabilities.

Tips for selecting the best silk screen printer include evaluating the machine's ease of use and maintenance requirements, as user-friendly interfaces can significantly reduce training time. Also, look for printers that offer comprehensive support and warranty options, as these can save costs in the long run. Finally, always seek out user reviews and case studies to gauge the performance and reliability of different models in real-world settings.

When selecting a silk screen printer for your printing needs, comparing pricing and service options is crucial to ensure you receive the best value for your investment. Industry reports indicate that the average cost for quality silk screen printing ranges from $2 to $10 per square foot, depending on factors such as complexity, color choices, and volume. Large orders typically yield lower per-unit costs due to economies of scale, while custom designs often incur higher fees. Understanding the pricing structure can help mitigate surprises and enable you to budget effectively.

Beyond pricing, the quality of service provided by potential printers plays a critical role in choosing the right partner. A report from the National Association of Printing Manufacturers indicates that the turnaround time for silk screen printing can vary significantly, from a few days for standard designs to several weeks for more complex orders. When assessing service options, consider factors such as customer support availability, communication responsiveness, and the ability to meet deadlines. High-quality service can make all the difference in ensuring that your project runs smoothly, meets your expectations, and is delivered on time, reinforcing the significance of not just the cost but also the overall service experience.

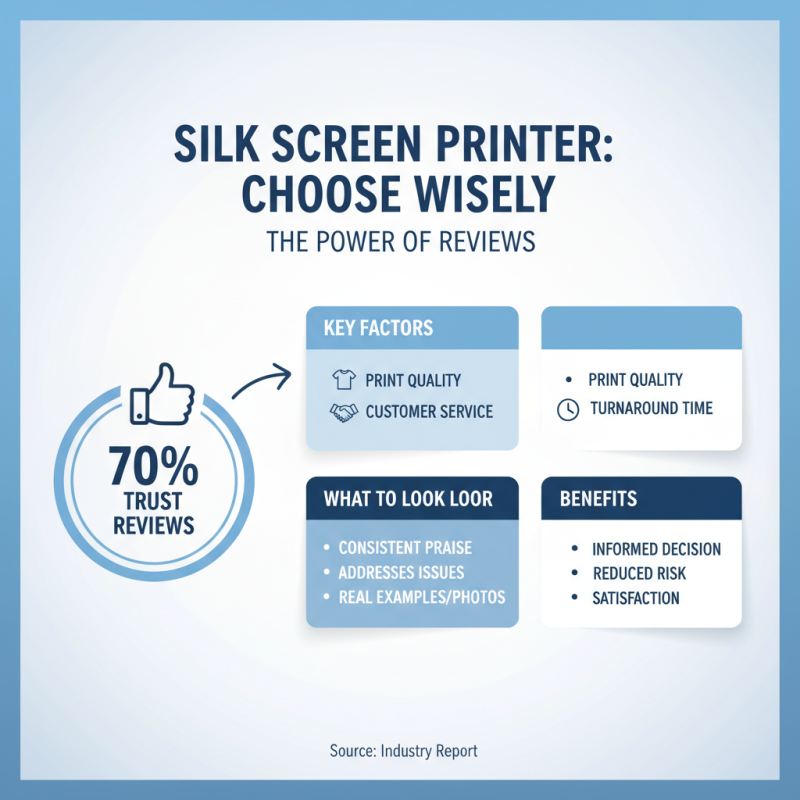

When selecting a silk screen printer, customer reviews and recommendations can significantly influence your decision-making process. A recent industry report highlighted that around 70% of consumers trust online reviews as much as personal recommendations. This statistic underscores the importance of researching feedback from individuals and businesses that have previously used the services of a potential printing provider. Look for trends in the reviews regarding print quality, customer service, and turnaround time, as these are critical factors influencing satisfaction.

Tips: Check multiple platforms for customer feedback to get a well-rounded view. Sites like Yelp, Google Reviews, and industry-specific forums often provide insightful comments. Pay attention to both positive and negative reviews; understanding common complaints can help you gauge whether a company can meet your specific needs.

Additionally, consider seeking out recommendations from local business networks or social media groups. A connection within the industry can lead you to printers with a proven track record in quality and reliability. According to the Printing Industries of America, businesses that prioritize word-of-mouth referrals see growth rates double that of competitors who do not leverage customer recommendations effectively. This further illustrates the value of a strong feedback-driven approach when choosing a silk screen printer that aligns with your printing needs.