The burgeoning custom apparel market has led to a significant rise in demand for efficient and versatile printing solutions, particularly in the realm of shirt printing. According to a report by IBISWorld, the custom t-shirt printing industry has seen annual growth rates of approximately 5.3% over the past five years, indicative of a vibrant consumer base eager for personalized garments. Consequently, selecting the right machine for shirt printing is crucial for businesses aiming to thrive in this competitive environment.

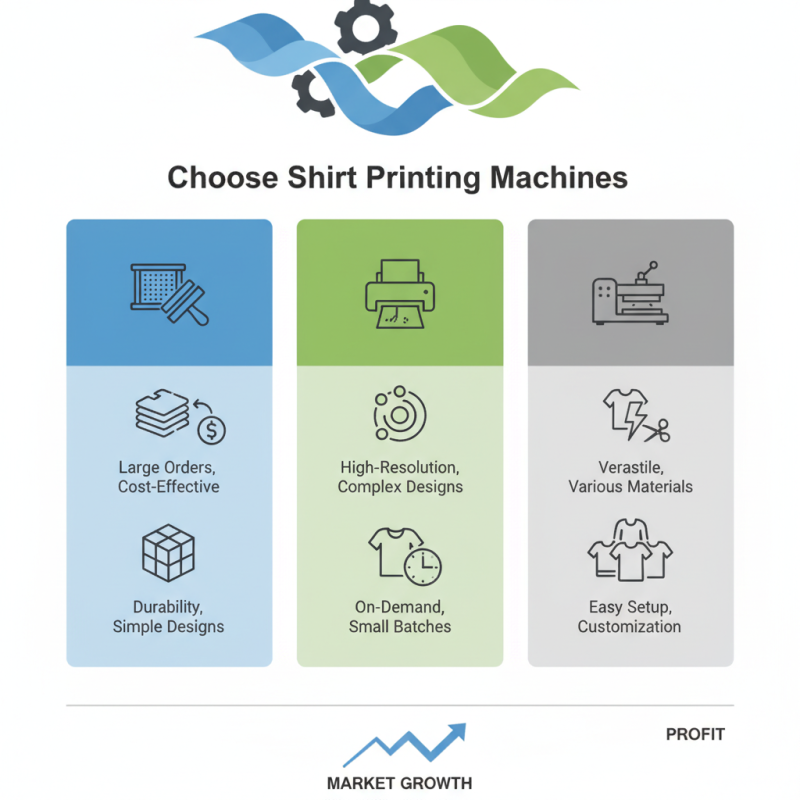

Choosing the best machine for shirt printing requires a thorough understanding of various technologies, including screen printing, direct-to-garment (DTG) printing, and heat transfer methods. Each of these methodologies offers distinct advantages and challenges, affecting not only print quality but also production speed and cost-effectiveness. For instance, DTG printers have gained popularity due to their ability to deliver high-resolution designs on-demand, while screen printing remains a go-to solution for large orders because of its efficiency and scalability. As the market continues to evolve, the right machine for shirt printing can be the defining factor in meeting customer expectations and maximizing profit margins.

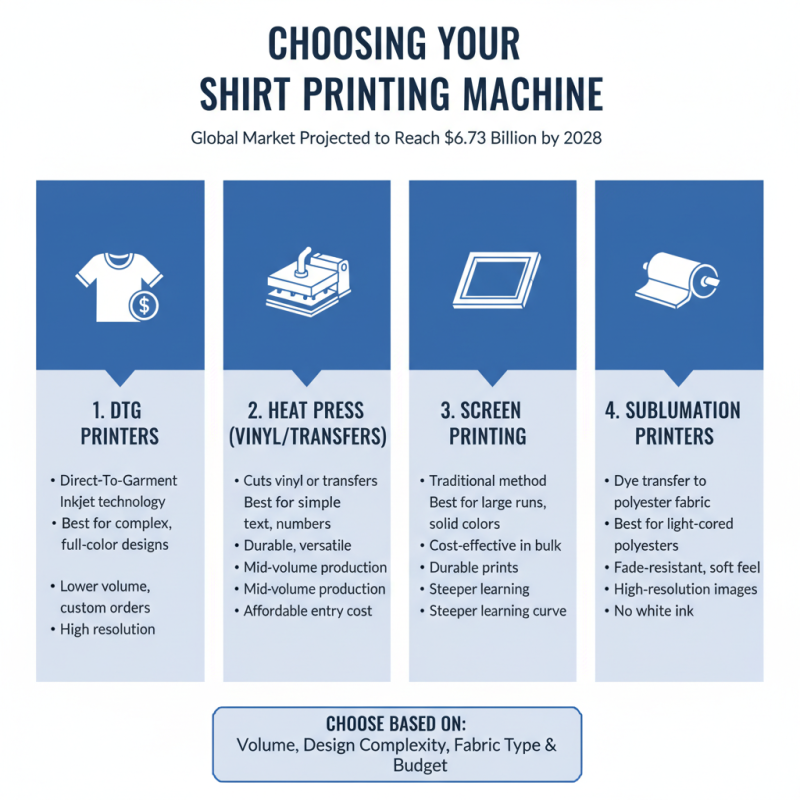

When it comes to choosing the best machine for shirt printing, understanding the different types of machines available is crucial. The market has seen significant growth over the years, with the global shirt printing market projected to reach approximately $6.73 billion by 2028, according to industry reports. This surge is driven by the rising demand for custom apparel, which has led to the development of various technologies tailored for different printing needs.

One of the most popular types of shirt printing machines is the direct-to-garment (DTG) printer. This method allows for high-quality prints on demand, making it ideal for businesses focusing on small orders or one-off designs. As per recent studies, DTG printing has captured a significant share of the market due to its ability to print complex graphics with vibrant colors. Alternatively, screen printing remains a favorite for larger production runs due to its cost-effectiveness and durability, especially with designs that require fewer colors. According to industry insights, screen printing is expected to maintain its relevance, especially among bulk orders, owing to its long-standing reputation for quality and efficiency.

Additionally, heat transfer printing has gained popularity, especially among those looking to enter the market with a lower investment. This method allows for quick and versatile designs, catering to both small and large-scale productions. Reports indicate that the heat transfer segment is expected to grow as new technologies emerge, making the process more efficient and less labor-intensive. By understanding these printing methods, businesses can make informed decisions that align with their production needs and market demands.

When selecting a printing machine for shirts, there are several key features to consider that can greatly influence both the quality and efficiency of your printing process. First, the type of printing technology is crucial. Common methods include screen printing, direct-to-garment (DTG) printing, and heat transfer printing. Each method has its advantages and limitations, so it's important to evaluate the volume of production, the complexity of designs, and the types of fabrics you'll be working with. For example, DTG is ideal for intricate designs and small batches, while screen printing excels in high-volume orders.

Another important consideration is the machine’s printing speed and capacity. If your business demands a quick turnaround, you'll want a machine that can handle a high volume of shirts in a short period. Assessing the maximum print size is also essential; ensure that the machine accommodates your typical shirt sizes and design formats. Additionally, features such as user-friendly interfaces, maintenance ease, and the availability of support resources can make a significant difference in your overall experience. Investing in a machine that combines quality, speed, and reliability will help you meet your production goals and satisfy your customers.

| Feature | Description | Importance Level |

|---|---|---|

| Print Quality | Resolution capabilities, color accuracy, and image sharpness. | High |

| Speed | Number of shirts printed per hour. | Medium |

| Ease of Use | User-friendly design and software interface. | High |

| Cost of Operation | Maintenance costs, ink consumption, and energy usage. | Medium |

| Portability | Weight and ease of transportation. | Low |

| Support and Community | Availability of technical support and user communities. | High |

| Versatility | Ability to print on different fabrics and materials. | High |

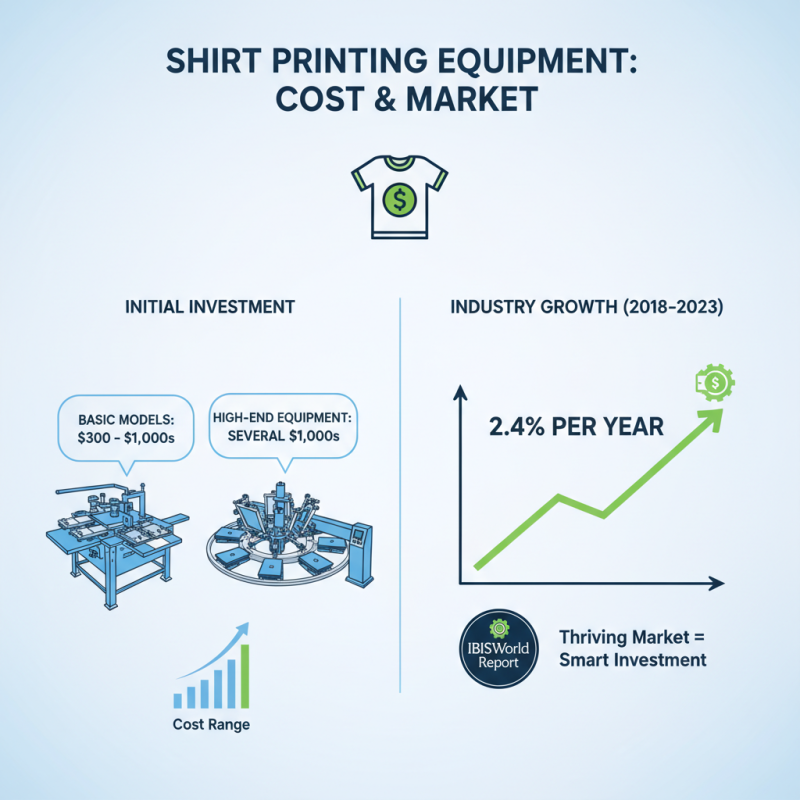

When embarking on a journey into shirt printing, a thorough cost analysis is essential for budgeting your equipment effectively. The initial investment in printing machines can vary significantly, ranging from a few hundred dollars for basic models to several thousand for high-end equipment. According to a report by IBISWorld, the screen printing industry has seen a steady growth rate of about 2.4% per year over the last five years, indicating a thriving market that rewards those who invest wisely in quality machinery.

In addition to the purchase price, consider ongoing costs such as maintenance, inks, and other consumables. The industry average for maintenance can range from 5% to 10% of the machine's initial cost annually. Furthermore, specialized inks and materials can add another layer of expense; for example, high-quality plastisol inks can cost between $30 to $80 per gallon, depending on the formula. By understanding these factors and projecting a budget that includes both fixed and variable costs, businesses can position themselves for success in the competitive shirt printing landscape.

When selecting the best machine for shirt printing, evaluating print quality and speed is essential to meet your specific needs. According to the latest data from Smithers Pira, the global digital textile printing market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of 20% by 2026. This growth highlights the increasing demand for high-quality prints that also prioritize speed and efficiency in production.

To ensure high print quality, consider machines that utilize advanced printing technologies such as direct-to-garment (DTG) or dye-sublimation. Research shows that DTG printers can achieve resolutions up to 1440 dpi, delivering vibrant colors and intricate designs that enhance the overall quality of the printed shirts. Additionally, it's important to assess the printer’s ink usage, as eco-friendly inks can not only improve print quality but also appeal to eco-conscious consumers.

Speed is another critical factor that cannot be overlooked. A report by Freedonia Group illustrates that businesses are increasingly opting for machines that can produce at least 100 shirts per hour for efficient operations without sacrificing quality. When choosing a printing machine, you should also consider setup times and ease of operation, as machines that minimize downtime can considerably enhance productivity, particularly in high-demand environments. By focusing on these aspects, you can select a shirt printing machine that aligns with your business goals and customer expectations.

When it comes to maintaining printing machines for shirt production, proper care is essential to ensure longevity and optimal performance. Regular cleaning of the machine components, including the print heads and rollers, can prevent clogging and enhance the quality of the prints. It's advisable to follow the manufacturer's guidelines on cleaning techniques and recommended cleaning solutions to avoid damage. Additionally, keeping the workspace clean and free of dust will further protect the machine from contaminants that could affect its functionality.

Another vital aspect of maintenance is performing routine inspections to identify any wear and tear before they escalate into significant issues. Checking belts, gears, and electrical connections can save both time and money in the long run. Lubrication of moving parts should also be scheduled according to usage to reduce friction and prevent overheating. Furthermore, keeping records of maintenance activities will help track the machine's performance and schedule future maintenance efficiently. By implementing these practices, users can ensure their printing machines remain reliable and ready to produce high-quality prints for years to come.