In the fast-evolving printing industry, the demand for efficient and versatile machines is crucial. An Oval Printing Machine offers innovative solutions tailored to various business needs. Recent reports indicate that the global printing market is projected to reach over $500 billion by 2026, with growth fueled by digital advancements and customization demands.

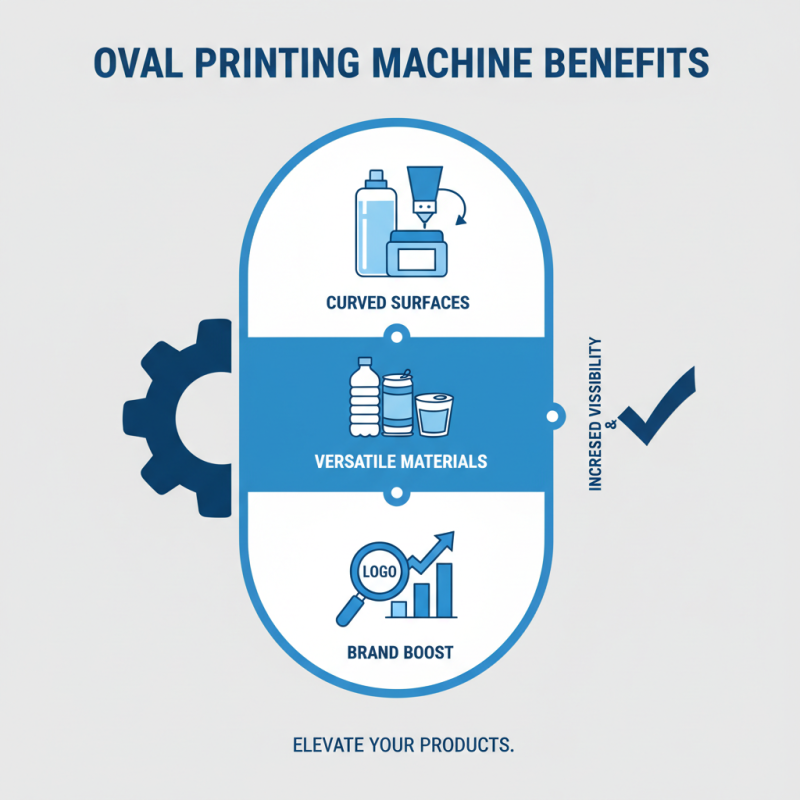

This machine stands out for its unique design, allowing for printing on curved surfaces. Businesses can enhance their product offerings with distinctive designs that catch consumer attention. In fact, studies show that unique packaging can increase consumer interest by 30%. However, it’s essential to remember that not all businesses will benefit equally. Implementation challenges and costs can impact small enterprises, making the decision to invest a critical one.

Choosing an Oval Printing Machine can be a game-changer, yet it demands careful consideration. It allows for high-quality prints while ensuring adaptability in diverse markets. Still, it's important to weigh the costs and training requirements before diving into this technology. A well-informed decision can lead to impressive results, but ignorance may lead to missed opportunities.

Oval printing machines have become increasingly popular among businesses seeking efficient printing solutions. These machines provide the versatility necessary for various applications. They are ideal for printing on curved surfaces, such as bottles and jars. According to recent industry reports, the demand for specialized printing equipment is projected to grow by 5% annually over the next five years. This reflects the need for businesses to adapt to unique printing challenges.

One of the advantages of oval printing machines is their ability to produce high-quality prints quickly. Many businesses report a reduction in production time by nearly 30% after integrating these machines. However, not every company fully utilizes their potential. Some operators may struggle with calibration or maintenance, leading to inconsistent results. Proper training and understanding of the machine’s capabilities can help mitigate these issues.

Cost-effectiveness is another key factor that businesses consider. While the initial investment may be higher, the long-term savings can be significant. Companies often find they can save up to 15% on material costs due to decreased waste. Yet, finding skilled operators remains a challenge. As technology advances, continuous learning and adaptation are crucial to maximizing the benefits of oval printing machines.

Choosing an oval printing machine can greatly benefit your business. These machines specialize in printing on curved surfaces. This is ideal for products like bottles and jars. The ability to print on various materials enhances your product appeal. Businesses see a boost in brand visibility and recognition.

One major advantage is speed. Oval printing machines often operate faster than traditional methods. This efficiency leads to shorter production times. You can meet customer demands without delay. However, consider the learning curve for your staff. Not every operator may handle new technologies easily.

Tip: Invest time in training your employees. Proper knowledge will maximize machine potential.

Another benefit is versatility. These machines can handle different designs and sizes. This flexibility supports creative marketing strategies. Still, be mindful of quality control. Printing errors can occur, undermining your brand’s credibility.

Tip: Regular maintenance checks can prevent issues. Keep your machine in top shape to avoid costly mistakes.

When considering an oval printing machine, there are key features to evaluate. One important aspect is print quality. Machines that provide vibrant colors and sharp details make your products stand out. A high-resolution result can elevate your brand. Moreover, consistency in print quality is crucial. Variable outputs can lead to customer dissatisfaction.

Another feature to think about is versatility. Oval printing machines can handle various materials. From textiles to plastics, adaptability is a must. This flexibility allows businesses to explore new markets. However, not all machines perform well across all mediums. It's essential to assess your specific needs before making a choice.

Speed and efficiency also play significant roles. A faster machine can enhance production rates. Yet, it's vital to balance speed with quality. Rushing the process may lead to errors, wasting materials. Recognizing this trade-off is crucial for effective operations. While these machines can boost profitability, the learning curve can be steep. Understanding the technology before diving in can save time and resources.

Oval printing machines have a wide range of applications across various industries. Their unique shape allows for efficient printing on cylindrical objects. This capability makes them ideal for products like bottles and cans. Many beverage companies utilize oval printing for branding. The results can be captivating and robust.

In the cosmetic industry, oval printing offers a chance for unique designs. Makeup containers and skincare products often use this technology. The machine can create intricate graphics that stand out on the shelf. Many brands recognize that a visually appealing design is crucial for consumer attraction.

**Tip:** Consider testing different inks and finishes to enhance visual appeal. Not all colors work well on every surface.

Food packaging also benefits from oval printing. High-quality images and clear text can communicate essential information. Additionally, it gives a touch of elegance to the product. However, not every product fits into the oval mold perfectly. Understanding the limitations of the design is essential.

**Tip:** Always evaluate your product's shape before committing to an oval design. This can avoid costly mistakes later on.

| Industry | Application | Benefits of Oval Printing | Typical Materials |

|---|---|---|---|

| Food & Beverage | Labeling bottles and packaging | Enhanced visibility and brand recognition | Glass, Plastic |

| Cosmetics | Printing on jars and tubes | High-quality finishes and vibrant colors | Glass, Aluminum |

| Pharmaceuticals | Packaging and labeling | Compliance with regulations and clear instructions | Plastic, Paper |

| Automotive | Printing parts and components | Durability and resistance to wear | Metal, Plastic |

| Textiles | Custom designs on fabrics | Unlimited design possibilities | Cotton, Polyester |

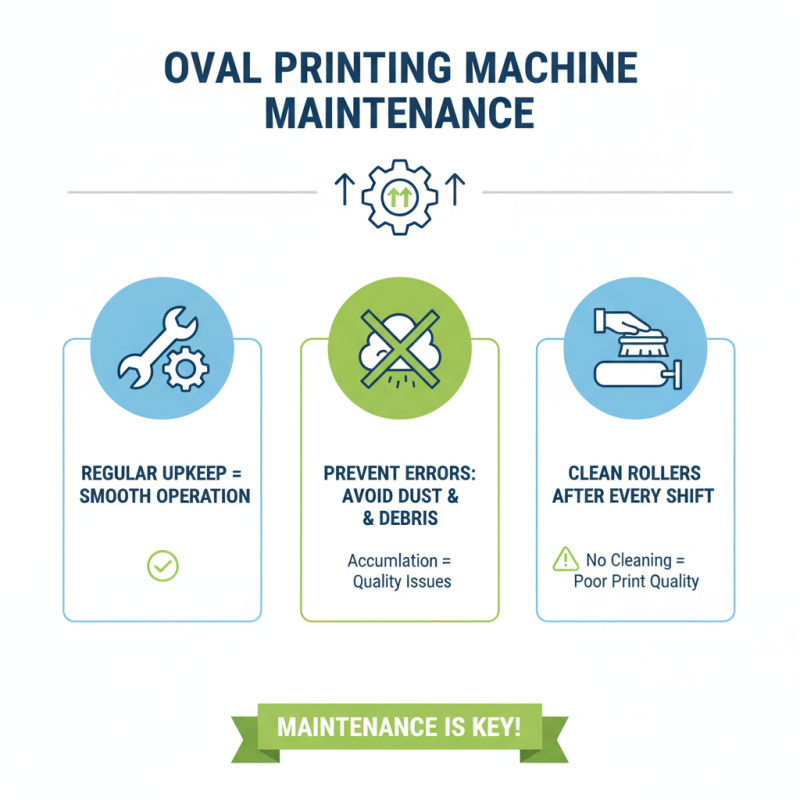

When it comes to oval printing machines, maintenance is key. Regular upkeep ensures that your machine runs smoothly. Dust and debris can accumulate over time. This can lead to printing errors. Cleaning the rollers is necessary after every shift. Not doing this could affect print quality significantly.

Optimization is just as important as maintenance. Adjusting the ink settings can enhance the vibrancy of colors. Experimenting with different materials can also yield better results. However, changes might not always produce the desired outcome. It’s essential to track these adjustments closely. Keeping a log can help identify patterns and issues.

Sometimes, you might encounter unexpected problems. Ink smudging is a common issue. This can happen due to various factors, including humidity. Being aware of these conditions is crucial. Your machine thrives in specific environments. If you neglect this, be prepared for a frustrating day ahead.