In the fast-paced world of fashion, choosing the right Clothing Printing Machine can be challenging for small businesses. This decision can significantly impact product quality and production speed. As we look ahead to 2026, advancements in technology are shaping the landscape of clothing printing.

Small businesses, often on tight budgets, seek machines that balance cost with reliable performance. The right Clothing Printing Machine should offer versatility for different fabrics and designs. Some companies struggle to find equipment that can handle unique projects without breaking the bank.

Investing in advanced printing technology is crucial. Many small brands feel overwhelmed by choices despite their clear vision. They risk stagnation in a competitive market if they fail to adapt. Therefore, understanding features like resolution, speed, and ease of use is essential as we navigate the evolving printing industry.

When it comes to clothing printing technologies for small businesses in 2026, several options stand out. Direct-to-Garment (DTG) printing offers vibrant colors and fine details. This method allows businesses to print complex designs directly onto fabric. However, it might not be cost-effective for bulk orders. Managing ink costs is crucial here.

Another popular choice is Heat Transfer Printing. It’s user-friendly and perfect for small runs. You simply print the design on transfer paper and apply heat. The downside? This method often results in a less durable finish, which may not satisfy some customers. Business owners should consider how frequently designs need to be reproduced.

Sublimation printing is gaining traction for its ability to produce long-lasting, high-quality prints on polyester fabrics. It involves dyeing the fabric, creating a seamless look. However, it can limit creativity when it comes to fabric choices. Small business owners must reflect on their target market. Finding the right balance between quality and cost is essential for success.

The clothing printing industry is experiencing significant growth, particularly among small enterprises. According to a recent report by Allied Market Research, the global market is projected to reach $12.9 billion by 2026, driven by the increasing demand for customized apparel. Small businesses are tapping into this trend, capitalizing on unique designs and personalization options that appeal to consumers.

As competition intensifies, challenges arise. Many small businesses struggle with quality control and machine maintenance, leading to inconsistent results. The need for high-quality printing is essential, yet small businesses may not always have access to advanced technology. While newer, more efficient machines are expensive, investing in reliable equipment often proves beneficial in the long run. Adopting a print-on-demand model can also mitigate upfront costs and waste.

Consumer preferences are shifting towards sustainable practices. Many customers favor sustainable materials and eco-friendly printing methods. Small businesses must adapt to these changing attitudes or risk losing market share. The balance between affordability and sustainability is delicate. Those who navigate this landscape with care will find opportunities for growth, while others may fall behind.

In 2026, small businesses increasingly seek efficient clothing printing solutions. Two popular technologies stand out: inkjet and direct-to-garment (DTG) printing. Each method has distinct advantages and challenges.

Inkjet printing offers flexibility. It adapts well to various fabrics and designs. Reports indicate that it accounts for over 50% of the market for custom apparel. The setup costs are generally lower, making it attractive for startups. However, maintaining print quality on textiles can be a challenge. Users must pay attention to ink compatibility. It is essential to select high-quality inks to avoid fading over time.

DTG printing shines with its high-quality output. This method allows intricate designs to be printed directly onto the fabric. The color vibrancy is often superior. A study shows that DTG is favored for small runs and detailed images. Yet, it can be less cost-effective for larger orders. The machines require regular maintenance, which can lead to downtime. Owners need to weigh the costs of repairs and supplies carefully.

Tip: Evaluate your production needs carefully before choosing a method. Determine the volume of orders you expect. Keep in mind your budget for maintenance and supplies. Investing in user training can significantly enhance your team’s efficiency. Make informed decisions to minimize errors and improve print quality. Consider the long-term implications of your choice.

Investing in clothing printing machines can be a substantial decision for small businesses. The initial costs vary significantly, typically ranging from $5,000 to $20,000. This figure depends on the machine's capacity and technology. For those on tighter budgets, entry-level options are sufficient. However, high-quality machines might yield better returns over time.

Long-term savings can be impressive. Research indicates that businesses using in-house printing can save up to 50% compared to outsourcing. Each printed shirt can cost around $5 to $8 when produced in-house, versus $10 to $20 when sent out. These savings accrue quickly, especially for businesses facing ongoing orders.

While considering these aspects, it’s vital to reflect on maintenance costs. Machines require regular upkeep and materials that can add to overhead. Some studies have shown that around 30% of small businesses underestimate these ongoing expenses. Investing in training for staff can also be a hidden cost. Training is necessary to fully utilize the machine’s capabilities, but many overlook this factor until issues arise.

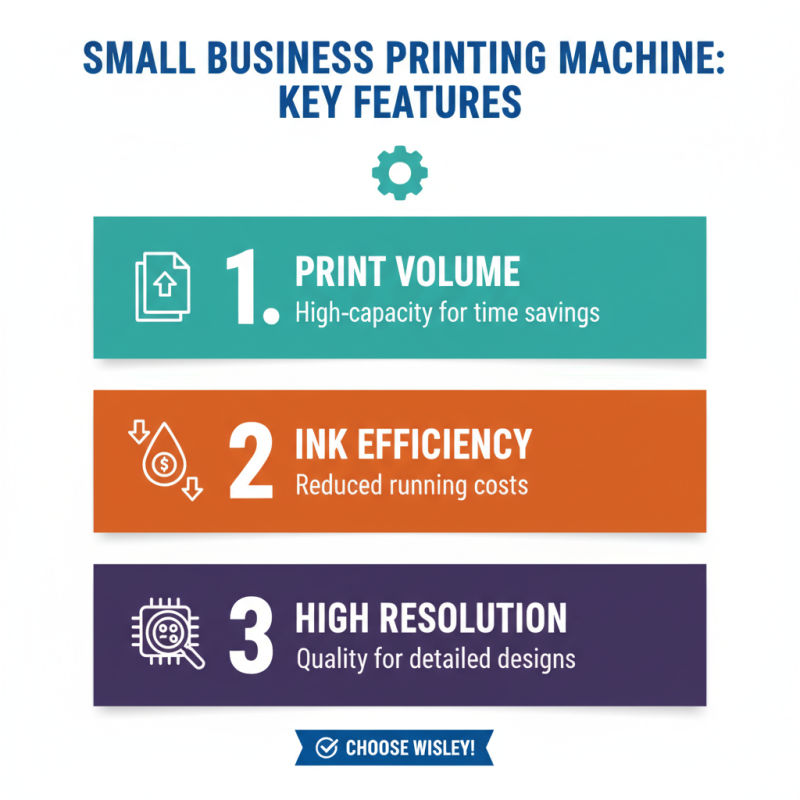

When choosing a printing machine for your small business, consider key features that meet your needs. Think about the volume of prints you plan to produce. A machine capable of handling high-volume tasks will save you time and energy. Look for machines with efficient ink usage to cut costs. If your startup focuses on detailed designs, choose printers that offer high-resolution capabilities.

Tips: Assess the durability of the machines you are considering. Some may require frequent repairs or replacements. Find out what other users say about maintenance. It’s vital to select machines that are easy to service. Look into warranty options as well.

Consider your workspace. Some printing machines need ample space and ventilation. Be aware of their power requirements. If your area has limited electrical outlets, this could become an issue. Test the setup before committing. It may feel cumbersome to relocate heavy equipment later. Evaluate how user-friendly the software is. Complicated systems can slow down your workflow.