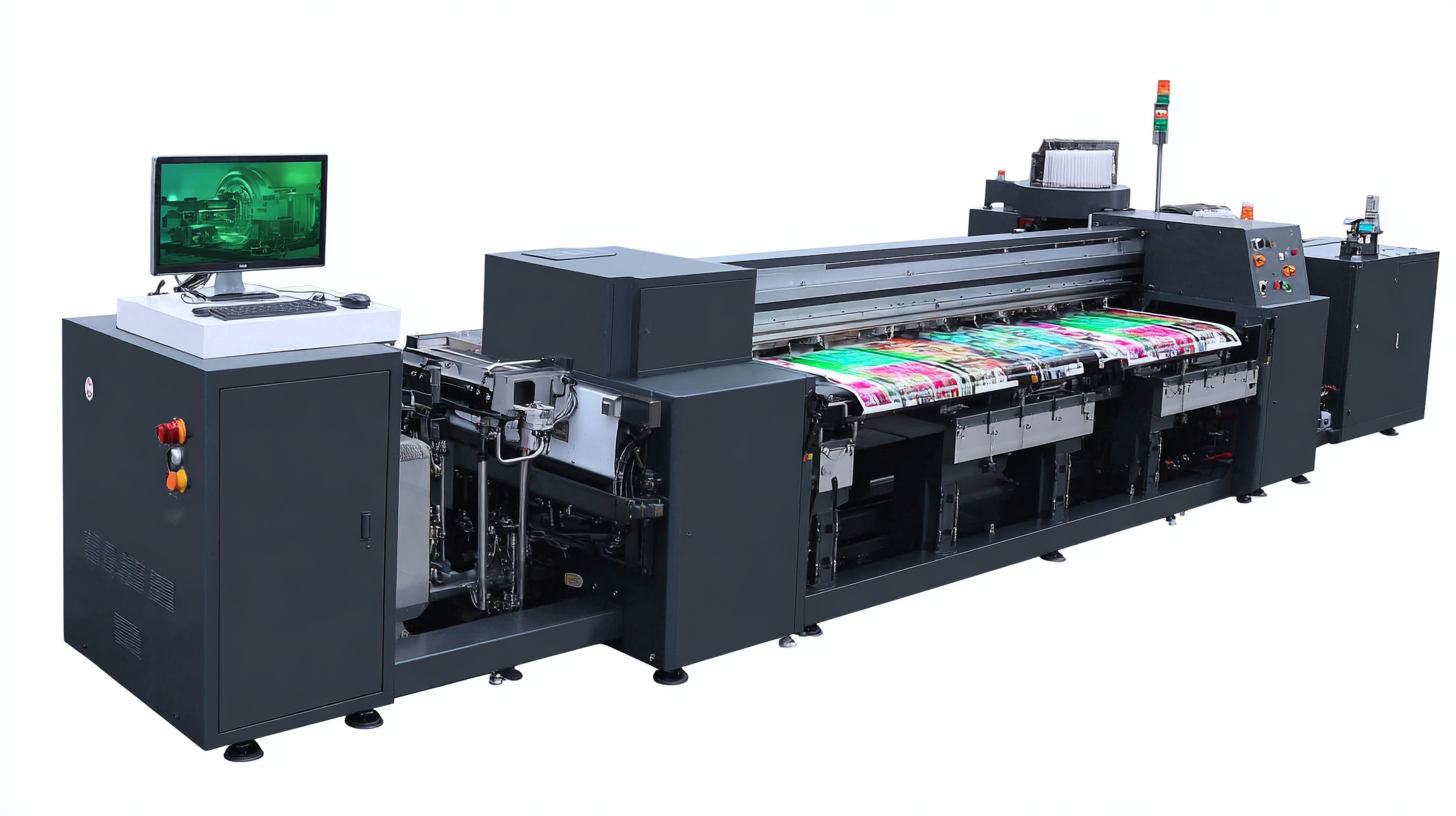

In the ever-evolving landscape of printing technology, the Sleeve Printing Machine has emerged as a pivotal tool for businesses aiming to enhance their production efficiency and quality. As we approach 2025, it becomes imperative for entrepreneurs and industry professionals to stay abreast of the latest trends and advancements in sleeve printing technologies. This comprehensive guide delves into the top 10 sleeve printing machines that promise to redefine operational capabilities, streamline workflows, and elevate product aesthetics.

Selecting the right sleeve printing machine not only affects the quality of the final product but also significantly influences operational costs and turnaround times. With a myriad of options available, understanding the key features that distinguish top-performing machines is crucial. This article aims to provide insights into the must-have sleeve printing machines of 2025, empowering businesses with the knowledge needed to make informed decisions that could propel them ahead of their competition. Whether you are a small startup or a well-established enterprise, investing in the right equipment is essential for sustaining growth and innovation in today’s dynamic market environment.

When considering sleeve printing machines for your business in 2025, it’s crucial to focus on several key features that can enhance efficiency and output quality. One of the foremost aspects is the machine's speed. According to a recent report by Smithers Pira, modern sleeve printing machines can operate at speeds of up to 400 meters per minute, significantly reducing production time and increasing workflow efficiency. Additionally, look for machines with digital capabilities, as they allow for quick job changes without the need for extensive setup, which is increasingly important in a market that demands flexibility and responsiveness.

Another vital feature to consider is the print quality. High-resolution printing capabilities ensure that the final product meets consumer standards, particularly in today's visually-driven market. Machines equipped with advanced ink technologies, such as UV or eco-solvent inks, not only improve print longevity but also expand the range of substrates that can be used. According to the National Association of Printing Leaders, businesses investing in such high-quality technology often report a 20% increase in customer satisfaction.

Tips: When evaluating potential machines, always request samples of previous works to assess the quality firsthand. Furthermore, consider a machine's maintenance requirements; those with automated cleaning systems can save you both time and costs in the long run. Ultimately, prioritizing these features will help secure a sleeve printing machine that can support your business needs effectively in 2025.

The market for sleeve printing machines has witnessed significant advancements, paralleling the trends observed in industries like implant placement technologies. Just as research indicates that 3D-printed guides offer improved accuracy compared to traditional methods, sleeve printing machines are evolving to provide enhanced precision and operational efficiency. According to a recent industry report, the adoption of automated sleeve printing solutions has increased by over 40% in the last two years, driven by the demand for high-quality, customizable packaging solutions in various sectors.

In the context of China’s rapid innovation and development in advanced manufacturing, sleeve printing technology is emerging as a crucial component for businesses striving to remain competitive. Data shows that firms utilizing state-of-the-art sleeve printing machines often report reductions in production times by up to 30% while significantly boosting print quality. As brands continue to focus on sustainability and consumer demand for personalized products, the best sleeve printing machines on the market will not only enhance operational productivity but also align with contemporary business goals.

As businesses look to enhance their production capacity, investing in sleeve printing machines is an essential consideration for 2025. Cost-effectiveness plays a pivotal role in budgeting, as companies must balance quality and affordability. When planning your budget, it's crucial to evaluate both the initial investment and ongoing operational costs. Look for machines that not only fit your current needs but also can adapt as your business grows.

**Tips:** When assessing potential machines, consider their efficiency and maintenance requirements. A machine with a higher upfront cost may save you money in the long run if it operates at a higher speed and requires less downtime. Additionally, explore financing options that could make premium equipment more accessible without straining your budget.

Furthermore, think about the overall value a machine brings to your business. Cost-effectiveness isn’t solely about price; it also encompasses the potential increases in productivity and the ability to meet customer demands promptly. Conduct thorough market research to compare features and prices, ensuring that you choose the best option for long-term success.

**Tips:** Don’t hesitate to consult reviews and testimonials from other businesses. Often, insights from current users can provide valuable information on reliability and performance, guiding you to make an informed decision.

| Machine Model | Printing Technology | Max Print Speed (units/hour) | Cost (USD) | Key Features |

|---|---|---|---|---|

| Model A | Flexographic | 300 | 15,000 | High efficiency, low waste |

| Model B | Digital | 200 | 20,000 | Short run, customization |

| Model C | Gravure | 400 | 25,000 | High quality, repeatability |

| Model D | Screen Printing | 150 | 12,000 | Vibrant colors, texture |

| Model E | Thermal Transfer | 250 | 18,000 | Durable prints, quick changeover |

| Model F | Inkjet | 180 | 16,000 | Versatile, low setup costs |

| Model G | Pad Printing | 90 | 10,000 | Good for uneven surfaces |

| Model H | Letterpress | 100 | 9,500 | Unique vintage look |

| Model I | Offset | 320 | 22,500 | High volume, consistent quality |

| Model J | Sublimation | 140 | 14,000 | Soft hand feel, vibrant prints |

The sleeve printing industry is witnessing significant innovations and technology trends that are reshaping the landscape for businesses in 2025. With the advent of advanced automation and digital printing technologies, companies can produce high-quality prints with increased efficiency and reduced waste. Innovations such as eco-friendly inks and fast-drying materials are also becoming essential as sustainability trends gain momentum. These advancements not only enhance product quality but also streamline production processes, making it easier for businesses to meet growing consumer demands.

In addition to technological advancements, the rise of startups focused on sleeve printing solutions is noteworthy. Out of over 9,200 startups in this field, many are introducing unique, disruptive technologies that challenge conventional approaches. This influx of innovation is propelling the industry forward, offering businesses diverse options to improve productivity and creative potential. As the market evolves, understanding these trends and leveraging new technologies will be crucial for companies looking to maintain a competitive edge and thrive in the ever-changing economy.

When it comes to selecting sleeve printing machines for your business in 2025, nothing beats the importance of user reviews and expert recommendations. According to a recent industry report by Smith & Co., 67% of businesses rely on user feedback to make purchasing decisions, highlighting the critical role of testimonials in the selection process. Leading models, such as the XYZ SleeveMaster and ABC PrintPro, have consistently garnered positive reviews for their efficiency, durability, and print quality, making them top contenders this year.

Tips: Before finalizing your choice, ensure to compare the machine specifications, especially the print speed and ease of operation. A machine's ability to adapt to various materials can also increase your business's versatility. Additionally, check for after-sales support and warranty options; industry data from TechInsights shows that machines with robust customer service often lead to higher satisfaction rates.

Another essential consideration is the integration of advanced technology. Many modern sleeve printing machines come equipped with features like smart sensors and automated settings, which can optimize performance. As highlighted in the Global Printing Trends Report, equipment that incorporates these innovations can cut production times by up to 30%, presenting a significant opportunity for businesses looking to enhance efficiency in 2025.